Industry information

Company News

- Aluminum Curtain Wall: The Charm Window of Modern Architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum Curtain Wall: A Modern Interpretation of Architectural Aesthetics

- Aluminum veneer, understated luxury in modern architecture

- Hey guys, do you know? In the pursuit of personalized home decoration, there is a material

Industry dynamics

- Aluminum veneer: the charm of metal in the new trend of architecture

- Advantages and market applications of aluminum veneer

- Aluminum Curtain Youth: A City with Aluminum Colored Medals

- 2.0mm aluminum veneer produced using wire drawing technology brings a new trend to construction engineering

- What are the environmental performance advantages of aluminum veneer?

Frequently asked questions

- What impact does the surface treatment method of aluminum veneer have on its price?

- Can aluminum veneer be used for building ceiling design?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- What is the color stability of aluminum veneer?

- How does the customizability of aluminum veneer affect the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

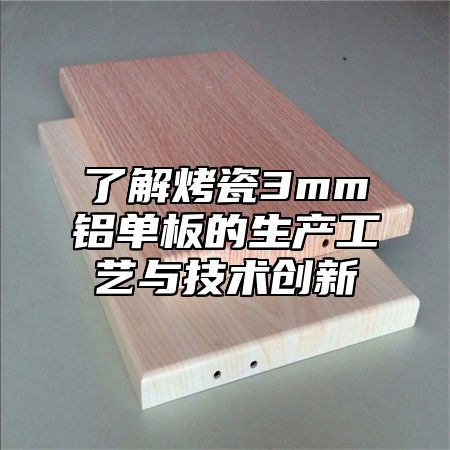

Understand the production process and technological innovation of porcelain fused to metal 3mm aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-02 05:40:25

- Click:0

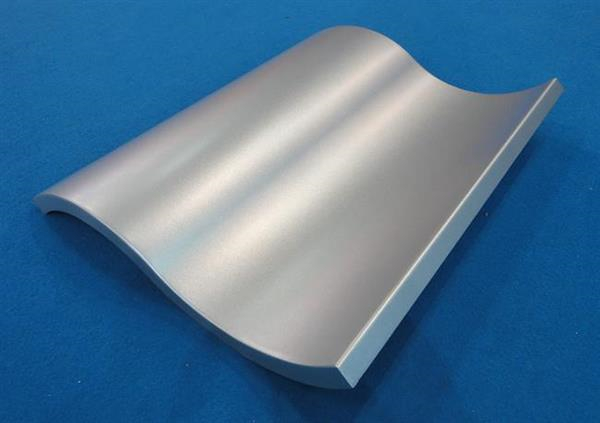

Porcelain veneer 3mmAluminum veneerIt is a new type of building material, and its production process and technological innovation play an important role in improving its quality and performance. This article will provide a detailed introduction to the production process and technological innovation of porcelain fused to metal 3mm aluminum veneer.

1、 Production process

The production process of porcelain fused to metal 3mm aluminum veneer mainly includes raw material preparation, sheet metal processing, surface treatment, coating and other links. The specific steps are as follows:

1. Raw material preparation

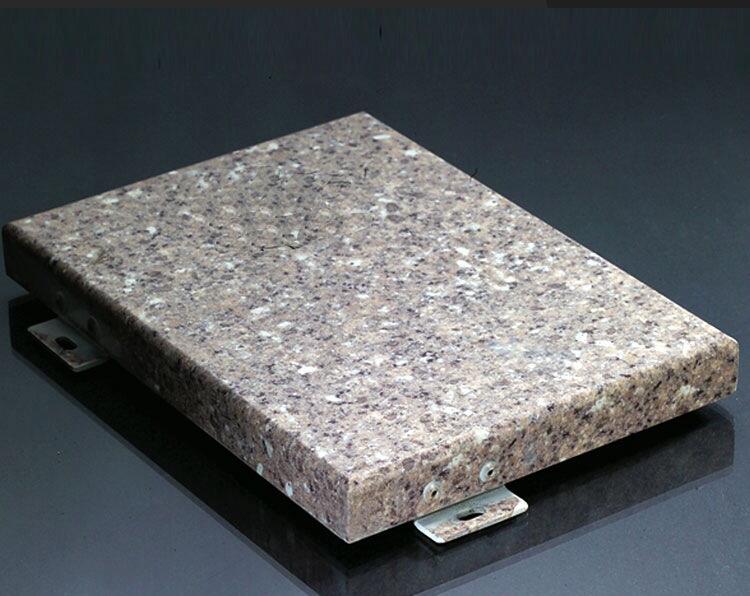

The main raw material for porcelain fused to metal 3mm aluminum veneer is high-strength aluminum alloy sheet, which has extremely strong corrosion resistance and wear resistance after special surface treatment. Additional auxiliary materials such as polyester resin and epoxy resin need to be added.

2. Sheet metal processing

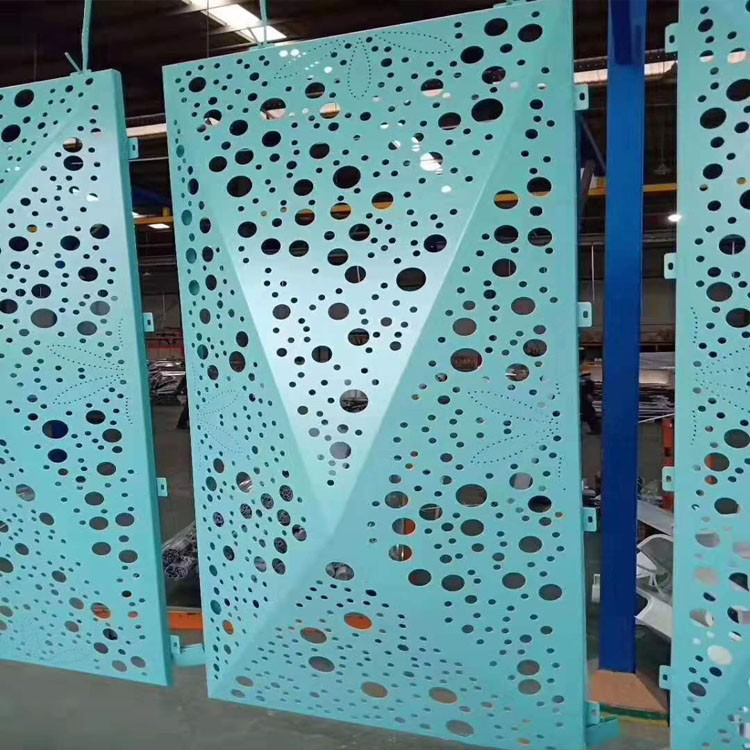

Sheet metal processing is the process of cutting, bending, stamping, and other processing steps on aluminum alloy sheets to meet different product shape and size requirements. In the process of sheet metal processing, advanced CNC equipment and process flow are required to ensure the accuracy and quality of the product.

3. Surface treatment

Surface treatment is one of the key processes for porcelain fused to metal 3mm aluminum veneer, with the aim of improving its surface corrosion resistance and decorative performance. Common surface treatment methods include anodizing, electrophoretic coating, powder coating, etc. Anodizing is the most commonly used method, which can form a dense oxide film and improve the corrosion resistance and hardness of the product.

4. Painting

Coating is the process of uniformly applying coatings such as polyester resin or epoxy resin onto the surface of 3mm aluminum veneer porcelain veneers. During the painting process, it is necessary to control the thickness and uniformity of the coating to ensure the quality and aesthetics of the product.

2、 Technological innovation

With the development of technology and the continuous improvement of people's requirements for building materials, the production process of porcelain fused to metal 3mm aluminum veneer is also constantly innovating and improving. Here are some common technological innovations:

1. Automated production line: Adopting an automated production line can greatly improve production efficiency and product quality stability, reduce manual intervention and errors. It can also achieve large-scale production and reduce costs.

2. Digital design: The use of digital design technology can achieve fast and accurate product design and manufacturing, avoiding errors and waste caused by traditional manual drawing. Advanced manufacturing technologies such as 3D printing can also be applied.

3. Environmental protection technology: Adopting environmental protection technology can reduce the impact and pollution on the environment, such as using low VOC coatings, recycling wastewater, and other measures. Renewable energy and other clean energy sources can also be used to support the production process.

Customer service QQ

Customer service QQ