Industry information

Company News

- The charm of aluminum veneer: it's not just about aesthetics!

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the beauty of architecture, simplicity is not simple

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum Curtain Wall: The Hidden Champion of Modern Architecture

Industry dynamics

- Aluminum Curtain Jianghu: Unveiling the "Face saving" Project of Modern Architecture

- Aluminum veneer: the beauty of architecture, simplicity is not simple

- What is the weather resistance of aluminum veneer?

- Design and application of hollow aluminum veneer for exterior walls

- Discussion on Energy saving and Environmental Protection Application of Aluminum Veneer

Frequently asked questions

- What is the color stability of aluminum veneer?

- Can the decorative effect of aluminum veneer be customized?

- Can the insulation function of aluminum veneer save energy?

- Can aluminum veneer be used for building ceiling design?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

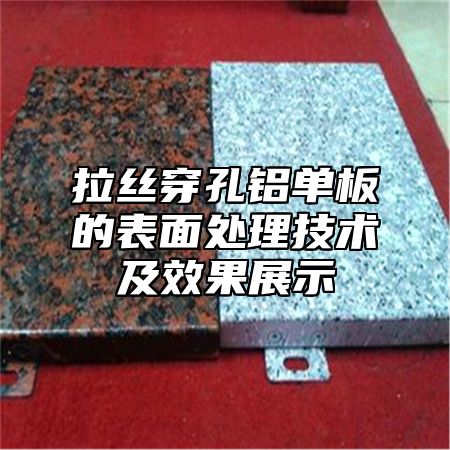

Surface treatment technology and effect display of brushed perforated aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 3, 2025 06:44:42

- Click:0

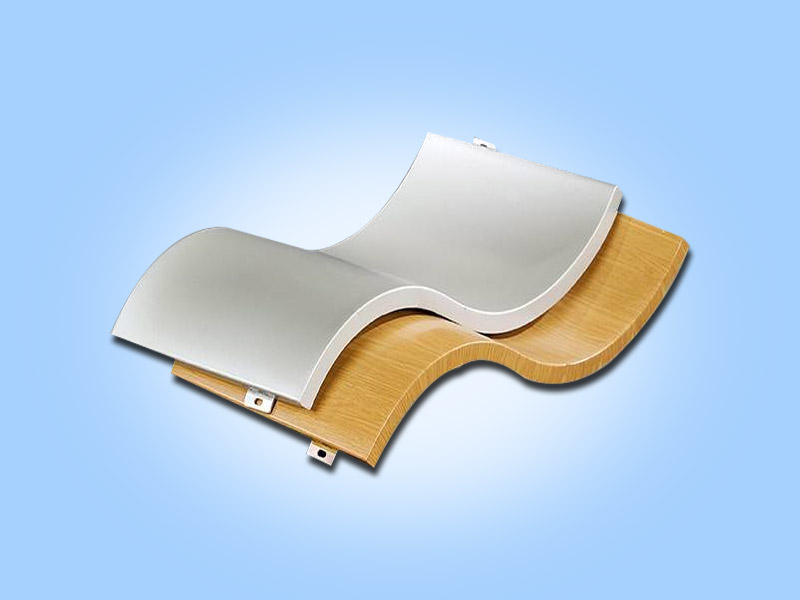

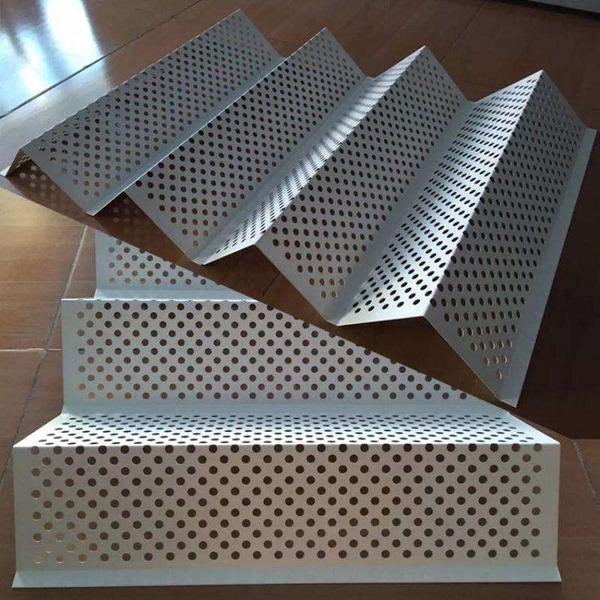

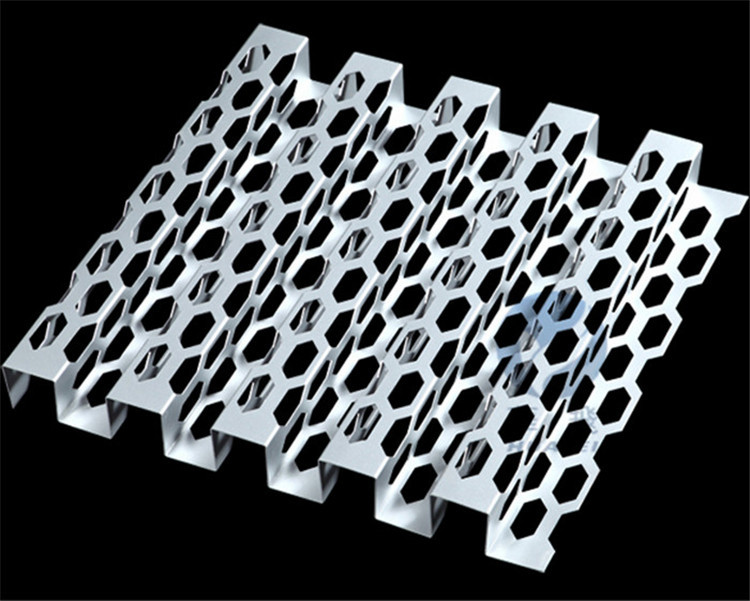

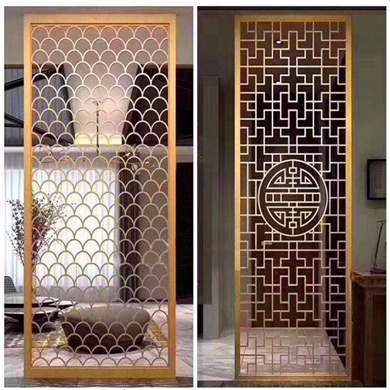

Wire drawing perforationAluminum veneerIt is a common building decoration material, and its surface treatment technology plays a crucial role in its aesthetics and service life. Next, we will provide a detailed introduction to the surface treatment technology and effect display of brushed perforated aluminum veneer.

1、 Surface treatment technology

1. Anodizing: Anodizing is one of the most common surface treatment techniques for brushed perforated aluminum veneer. This technology enhances the corrosion resistance and decorative properties of aluminum by electrolyzing it in an electrolyte solution to form an oxide film on its surface.

2. Spray coating: Spray coating is another commonly used surface treatment technique. This technology improves its corrosion resistance and decorative properties by spraying paint onto the surface of aluminum to form a uniform coating.

3. Fluorocarbon spraying: Fluorocarbon spraying is a high-end surface treatment technology that can improve the weather resistance and UV resistance of brushed perforated aluminum veneer. This technology improves its decorative and durability by spraying fluorocarbon coating onto the surface of aluminum to form a uniform coating.

2、 Effect display

1. Anodized brushed perforated aluminum veneer: After anodizing treatment, the surface of the brushed perforated aluminum veneer presents a unique metallic texture and has a good decorative effect. Due to the presence of oxide film, it also has good corrosion resistance and wear resistance.

2. Spray brushed perforated aluminum veneer: After spraying treatment, the surface of the brushed perforated aluminum veneer presents a smooth and uniform coating, which has a good decorative effect. The spray coating can also provide some anti-corrosion protection.

3. Fluorocarbon spray drawn perforated aluminum veneer: After fluorocarbon spray treatment, the surface of the drawn perforated aluminum veneer presents a high gloss and uniform coating, with good decorative effect and weather resistance. Fluorocarbon coatings also have good UV resistance and can maintain bright colors in sunlight.

3、 Conclusion

The surface treatment technology of brushed perforated aluminum veneer plays a crucial role in its aesthetics and service life. Different surface treatment techniques can provide different decorative and protective effects, and users can choose the appropriate surface treatment method according to their own needs. If you are considering choosing suitable decorative materials to decorate your building, you may want to consider brushed perforated aluminum veneer. It will definitely become a beautiful scenery in your architectural decoration.

Customer service QQ

Customer service QQ