Frequently asked questions

Company News

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Exploring the Aesthetics of Modern Architecture - Fashion Interpretation of Curtain Wall Aluminum Veneers

- Aluminum veneer: the "silver warrior" in modern architecture

- Aluminum veneer: the 'hidden hero' of modern architecture

- Aluminum veneer curtain wall, the fashionable choice for modern architecture

Industry dynamics

- Aluminum veneer: the beauty of architecture, a new choice for light luxury

- Aluminum veneer, the low-key fashion darling of the construction industry

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

- What are the surface treatment methods for curtain wall aluminum veneer?

- Exquisite aluminum veneer customization, making the building more modern

Frequently asked questions

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- Can aluminum veneer be used for building ceiling design?

- Can the insulation function of aluminum veneer save energy?

- What is the color stability of aluminum veneer?

- Will the use of aluminum veneer affect the ventilation effect of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What impact does the surface treatment method of aluminum veneer have on its price?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-28 20:33:30

- Click:0

Aluminum veneerWhat impact does the surface treatment method have on its price?

Abstract: This article will elaborate on the impact of surface treatment methods on the price of aluminum veneer from four aspects. These four aspects are: coating type, color selection, surface effect, and additional processes.

1、 Coating type

1. Fluorocarbon coating: Fluorocarbon coating is currently one of the most widely used surface treatment methods for aluminum veneer. It has excellent weather resistance and corrosion resistance, which can effectively protect the surface of aluminum veneer from natural environmental erosion. However, due to the high production process and raw material costs of fluorocarbon coatings, the price of aluminum veneer will also increase accordingly.

2. Polyester coating: Polyester coating is an economical and practical surface treatment method. It has good weather resistance and wear resistance, but compared to fluorocarbon coatings, polyester coatings have slightly poorer corrosion resistance. Due to the low production cost, the price of using polyester coating on the surface of aluminum veneer is relatively low.

3. Other coating types: In addition to fluorocarbon coatings and polyester coatings, there are also some other coating types to choose from, such as silicone coatings, acrylic coatings, etc. These coatings have different characteristics and applicability, and their prices may vary accordingly.

2、 Color selection

1. Standard color: The standard color of aluminum veneer is usually pre mixed and the production process is relatively simple, so the price is relatively low. Standard colors are suitable for most construction projects and can meet general needs.

2. Customized colors: If customers require special colors, customized production is required. This involves pigment blending and process adjustments, which increase production costs, resulting in higher prices for customized color aluminum veneers.

3. Metallic texture color: Aluminum veneer with metallic texture color is treated with special technology to present a metallic texture effect on its surface. The price of aluminum veneer in this color is relatively high because the production process is relatively complex and requires the use of special coatings and processing techniques.

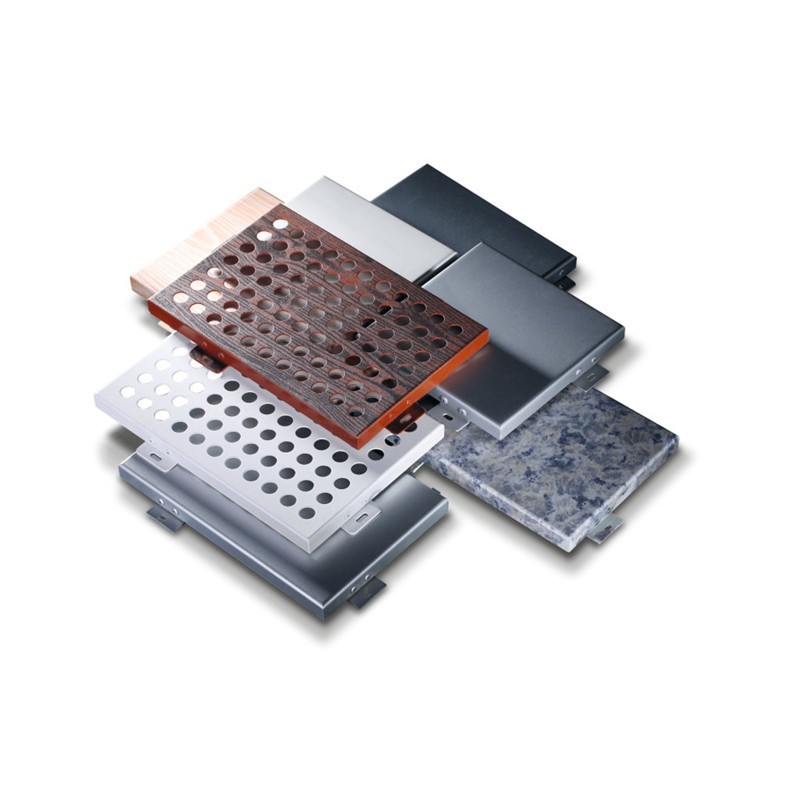

3、 Surface effect

1. Flat surface: Flat surface is the most common surface effect, characterized by simplicity and grandeur. Due to the relatively simple production process, the price of aluminum veneer with flat surface is relatively low.

2. Concave convex surface: The concave convex surface is made by special mold processing, which gives the aluminum veneer surface an uneven effect. The price of aluminum veneer with this surface effect is relatively high because the production process is relatively complex and requires the use of special molds and process technology.

3. Texture board surface: Texture board surface presents a texture effect on aluminum veneer by adding special particles to the coating. The price of aluminum veneer with this surface effect is relatively high because the production process is relatively complex and requires the use of special particles and process technology.

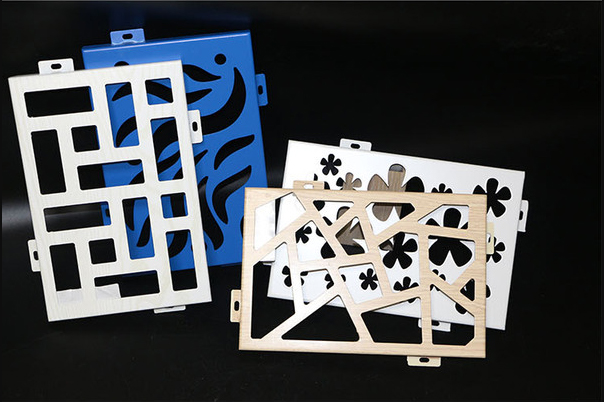

4、 Additional processes

1. Spray coating process: Spray coating process is a common additional process that can form various patterns and texts on the surface of aluminum veneer. The price of spraying technology depends on the complexity of the pattern and the requirements of the spraying process.

2. Embossing process: Embossing process can form various patterns and designs on the surface of aluminum veneer, increasing the decorative effect of aluminum veneer. The price of embossing technology depends on the complexity of the pattern and the requirements of the embossing process.

3. Anodizing process: Anodizing is a process of oxidizing the surface of aluminum veneer to improve its corrosion resistance and wear resistance. The price of anodizing process is relatively high because it requires the use of special equipment and process technology.

5、 Summary:

In summary, the surface treatment method of aluminum veneer has a significant impact on its price. The type of coating, color selection, surface effect, and additional processes can all lead to differences in the price of aluminum veneer. Therefore, when purchasing aluminum veneer, it is necessary to consider different surface treatment methods based on project requirements and budget to achieve the best cost-effectiveness.

Customer service QQ

Customer service QQ