Industry information

Company News

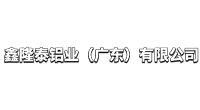

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the beauty of industry, the fashionable choice of modern architecture

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer: the 'hidden guardian' of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture, revealing the secrets behind it!

Industry dynamics

- Aluminum veneer: the "green clothing" of modern architecture

- Create a unique style and customize aluminum veneers to make the building more distinctive

- Aluminum veneer customization, creating a new trend of personalized space!

- Aluminum veneer manufacturer with excellent quality and good reputation

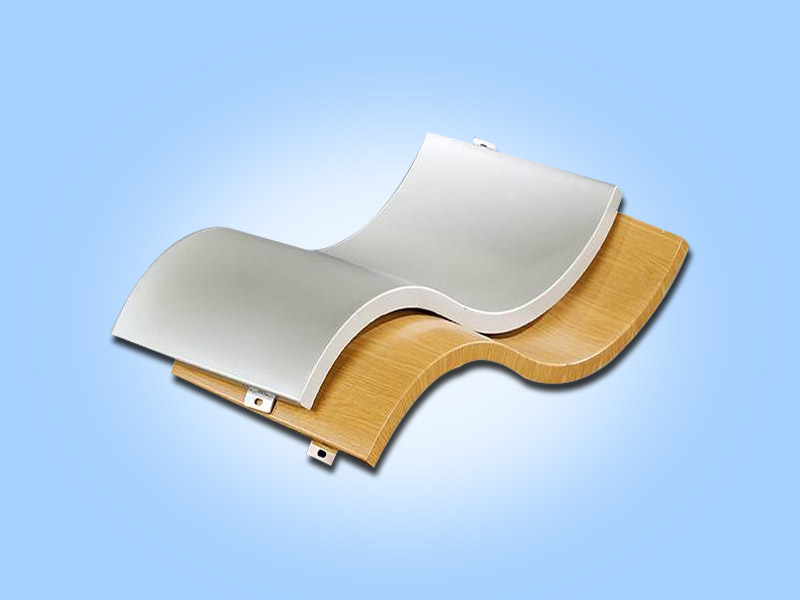

- Design and application of hollow aluminum veneer for exterior walls

Frequently asked questions

- What is the thermal expansion coefficient of aluminum veneer?

- What is the color stability of aluminum veneer?

- What impact does the surface treatment method of aluminum veneer have on its price?

- What impact does the thickness of aluminum veneer have on architectural design?

- Will the use of aluminum veneer affect the ventilation effect of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer customization process flow

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 20, 2025 06:25:46

- Click:0

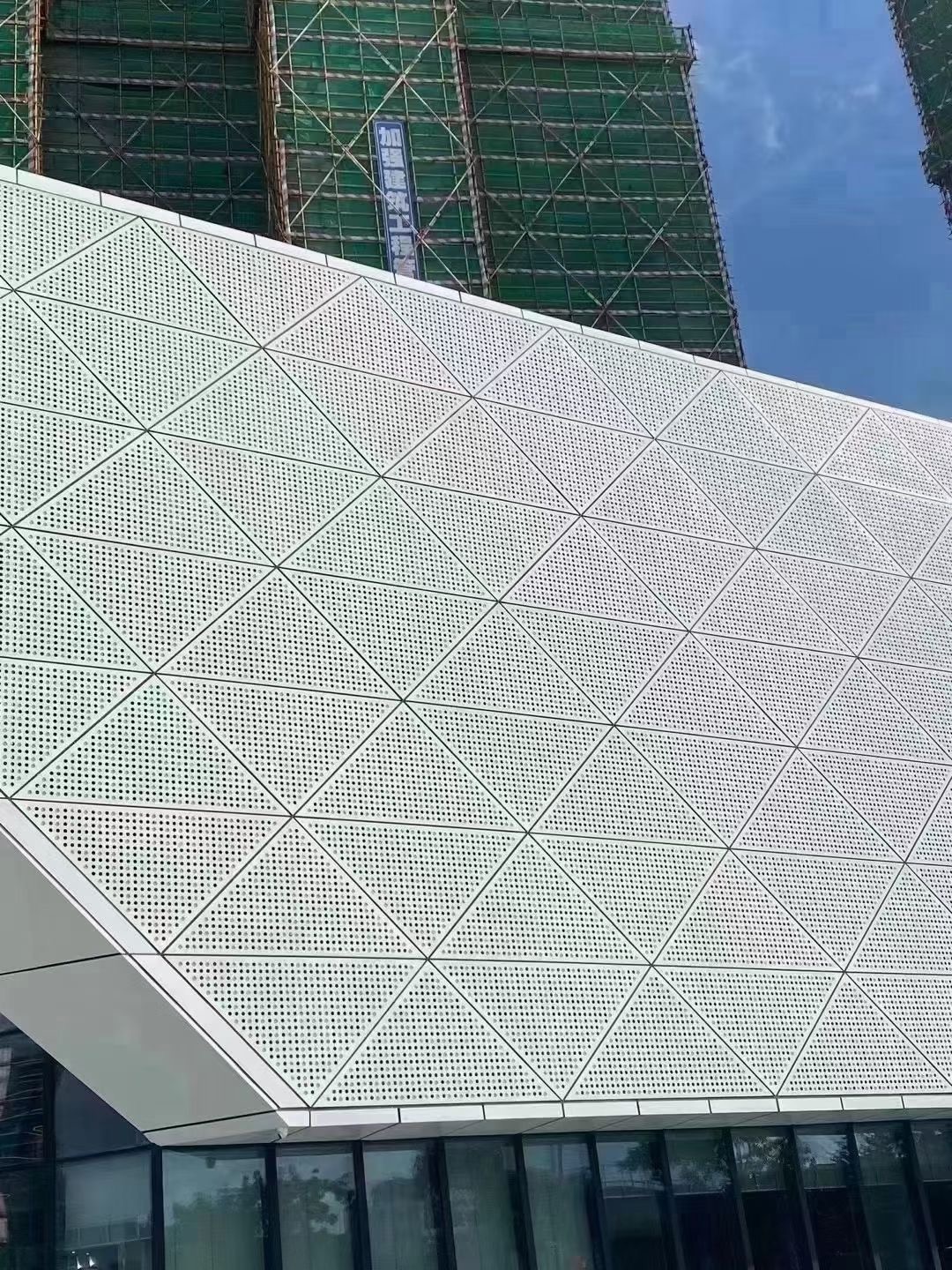

Aluminum veneerCustomization is a personalized customization service based on customer needs and requirements. When customizing aluminum veneer, a series of process flows are required to complete it. Below, we will provide a detailed introduction to the process of customizing aluminum veneer.

1、 Design phase

The design stage of customized aluminum veneer is the most important part of the entire process flow. In the design phase, product design needs to be based on customer needs and requirements, including the shape, color, size, surface treatment method, and other aspects of aluminum veneer design. At the same time, it is necessary to consider the usage environment and functional requirements of the product to ensure its quality and practicality.

2、 Material procurement stage

The material procurement stage for customized aluminum veneer is an important link in ensuring product quality. When purchasing materials, it is necessary to choose high-quality raw material suppliers and conduct strict quality inspection and testing on the raw materials to ensure that they meet the standards and requirements. At the same time, it is necessary to compare and analyze different types of aluminum veneers to select the most suitable product material.

3、 Processing and production stage

The processing and production stage of customized aluminum veneer is a key step in transforming design drawings into actual products. In the processing and production stage, advanced processing equipment such as CNC machine tools are needed to cut, bend, drill and process aluminum veneers to meet customer needs and requirements. Attention should be paid to precision and efficiency during the processing and production process to improve the quality and competitiveness of the product.

4、 Surface treatment stage

The surface treatment stage of customized aluminum veneer is an important step in beautifying and protecting the aluminum veneer. In the surface treatment stage, aluminum veneer needs to be treated according to different surface treatment methods (such as anodizing, electrophoretic coating, etc.) to achieve waterproof, fireproof, anti-corrosion and other effects. At the same time, surface printing, spraying and other treatments can be carried out according to customer needs and requirements to increase the beauty and decorative value of the product.

5、 Packaging and transportation stage

The packaging and transportation stage of customized aluminum veneer is a crucial step in ensuring the safe delivery of products to customers. During the packaging and transportation phase, it is necessary to package and label the aluminum veneer, and take appropriate transportation methods and measures to ensure that the product is not damaged or deformed during transportation. At the same time, it is necessary to recycle packaging materials to reduce resource waste and environmental pollution.

6、 Conclusion and Prospect

Through the introduction of the above aluminum veneer customization process, it can be seen that aluminum veneer customization requires strict control and management in multiple stages to ensure product quality and practicality. In the future, with the continuous advancement of technology and changes in market demand, the aluminum veneer industry will pay more attention to product innovation and service level improvement to meet the needs and expectations of consumers. At the same time, it is necessary to strengthen communication and cooperation with other fields to provide consumers with more comprehensive and objective selection criteria and service support. For enterprises, they should strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance their competitiveness and profitability. At the same time, it is necessary to strengthen cooperation and communication with other brands to jointly promote the development of the entire aluminum veneer industry.

Customer service QQ

Customer service QQ