Industry information

Company News

- Aluminum Curtain Wall: The 'Gorgeous Coat' of Modern Architecture

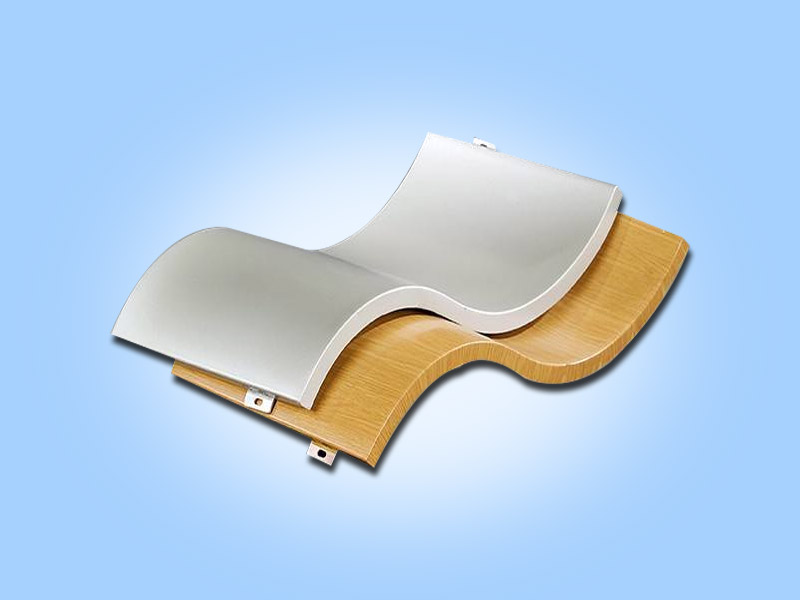

- Aluminum veneer customization: the perfect combination of personality and aesthetics

- Aluminum veneer: injecting new vitality into buildings

- Aluminum veneer: the 'invisible hero' of modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Curtain wall aluminum veneer: a perfect fusion of architectural aesthetics and practicality

- Aluminum veneer curtain wall, the "soft decoration" art of architectural aesthetics

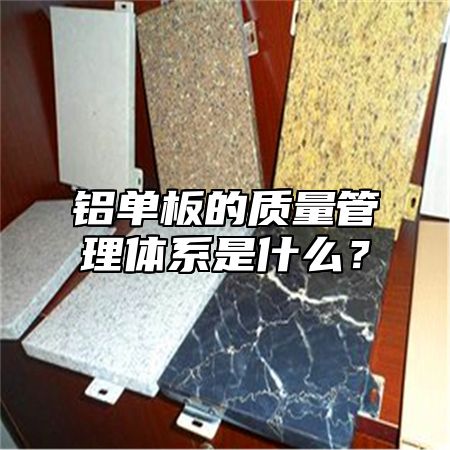

- Characteristics and application fields of stone patterned aluminum curtain wall

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm!

- Aluminum veneer: the fashionable outerwear of modern architecture

Frequently asked questions

- What impact does the surface treatment method of aluminum veneer have on its price?

- Can the insulation function of aluminum veneer save energy?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- What is the color stability of aluminum veneer?

- Can the decorative effect of aluminum veneer be customized?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the quality management system for aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 21, 2025 16:37:06

- Click:0

Aluminum veneerAs a common building material, its quality management system is also one of the key concerns in the construction industry. Below, we will provide a detailed introduction to the quality management system and implementation process of aluminum veneer.

1. Definition of Quality Management System

Quality management system refers to a complete set of management processes and standardized systems established by enterprises to ensure that products or services meet customer requirements and legal regulations. In the production of aluminum veneer, the quality management system includes the full process management and control from raw material procurement, production and processing to finished product delivery, aiming to improve product quality and customer satisfaction.

1. Quality Management System Standards

The production of aluminum veneer requires compliance with certain quality management system standards, such as ISO 9001:2015 (Quality Management System), GB/T 14886-2003 (Aluminum Alloy Building profiles), etc. These standards specify the management principles, processes, and requirements that aluminum veneer production enterprises should follow to ensure product quality meets national and industry standards.

1. Quality management organizational structure

Aluminum veneer production enterprises need to establish a sound quality management organizational structure, including multiple departments such as quality management, production, and technology, clarify the responsibilities and tasks of each department, and form a collaborative working mechanism. It is also necessary to establish a sound internal communication channel and information feedback mechanism to promptly address issues and improve work.

1. Raw material procurement management

Raw material procurement is an important link in the production of aluminum veneer, requiring strict quality inspection and supplier evaluation. Enterprises need to establish a sound raw material procurement management system, clarify procurement processes and responsible persons, evaluate and screen suppliers, and ensure the quality and stability of raw materials.

1. Production process management

The production process of aluminum veneer requires comprehensive monitoring and management, including production technology, equipment maintenance, personnel training, and other aspects. Enterprises need to establish a sound production process management system, develop detailed operating procedures and flowcharts, monitor and record the entire production process, and promptly identify and solve problems.

1. Finished product inspection and factory management

Aluminum veneer products require strict inspection and testing to ensure that the product quality meets standard requirements. Enterprises need to establish a sound system for finished product inspection and factory management, conduct comprehensive inspections and testing of finished products, and ensure that the quality and safety performance of the products meet the requirements. We also need to establish a comprehensive after-sales service system to provide customers with timely technical support and services.

The quality management system for aluminum veneer includes multiple aspects such as quality management system definition, quality management system standards, quality management organizational structure, raw material procurement management, production process management, finished product inspection, and factory management. Aluminum veneer production enterprises need to establish and improve their quality management system according to actual situations and needs, in order to ensure that product quality and customer satisfaction reach the best state. We also need to strengthen technological innovation and research and development efforts, constantly innovate and contribute to the sustainable development of the construction industry.

Customer service QQ

Customer service QQ