Industry information

Company News

- Aluminum veneer curtain wall, the new darling of modern architecture!

- Aluminum veneer customization, creating the beauty of exclusive space

- The Charm of Aluminum Veneer Curtain Walls: Unveiling the Beauty of Modern Architecture

- Aluminum veneer: a metal fashion show in modern architecture

- Aluminum veneer curtain wall, the "fashionable coat" of modern architecture

Industry dynamics

- What are the widespread applications of aluminum veneer in the construction industry?

- New trend of aluminum veneer, new darling of architectural aesthetics

- Aluminum veneer curtain wall: the beauty of architecture, with unique craftsmanship

- Aluminum veneer: the beauty of architecture, simplicity is not simple

- Aluminum veneer: an aesthetic weapon for modern architecture

Frequently asked questions

- How does the customizability of aluminum veneer affect the appearance of buildings?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- Can the decorative effect of aluminum veneer be customized?

- What impact does the surface treatment method of aluminum veneer have on its price?

- What is the color stability of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Fine processing! Analysis of Roll Coating and Carving Aluminum Veneer Process

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-02 05:01:32

- Click:0

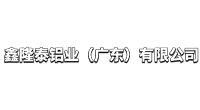

Roller coating carvingAluminum veneerIt is a new type of building decoration material that has been widely used in building decoration due to its unique decorative effect and superior performance. The aesthetic effect of this aluminum veneer is not accidental, but stems from its fine processing technology. This article will provide a detailed analysis of the process of roller coated carved aluminum veneer.

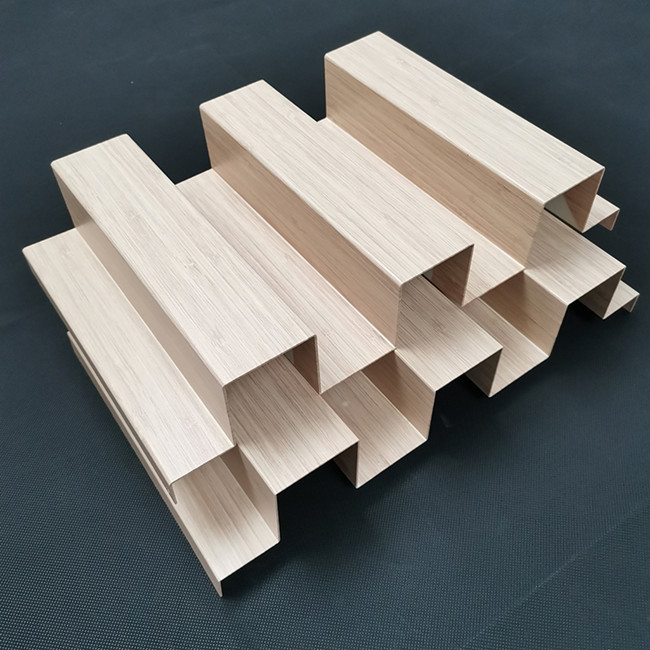

The production process of roll coated carved aluminum veneer mainly includes steps such as raw material preparation, roll coating, carving, polishing, and spraying. In the raw material preparation stage, it is necessary to select high-quality aluminum alloy materials and make them into the required size and shape through precise measurement and cutting. By using the roller coating process, a uniform coating is applied to the surface of the aluminum veneer to prevent oxidation and corrosion during use.

Next, through carving techniques, the patterns or text designed by the designer will be carved onto the surface of the aluminum veneer. This step requires the use of professional carving equipment and techniques to ensure the accuracy and quality of the carving. By using polishing technology, the surface of the carved aluminum veneer is polished to make it smoother and smoother.

By spraying technology, a layer of brightly colored coating is applied to the surface of aluminum veneer to enhance its decorative effect. This step requires the use of high-quality coatings and spraying equipment to ensure uniformity of spraying and durability of color.

The fine processing technology of roller coated carved aluminum veneer is the key to its aesthetic effect. By strictly controlling and finely operating each process, the surface quality and decorative effect of aluminum veneer can be ensured to reach the best state. For manufacturers of roll coated carved aluminum veneer, improving the accuracy and quality of production processes is very important. For consumers, choosing roll coated carved aluminum veneer with high-quality production technology is also very important.

Customer service QQ

Customer service QQ