Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer curtain wall, the "skin" art of modern architecture

- Aluminum veneer is not just a decoration on the exterior of buildings

- Aluminum veneer customization, creating an artistic journey of personalized space

- Curtain Wall Aluminum Veneer: A Modern Interpretation of Architectural Aesthetics

Industry dynamics

- Aluminum veneer: the secret weapon for creating fashionable buildings

- Is the service life of aluminum veneer long?

- Aluminum veneer customization, creating a new proposition for personalized space

- Have you ever thought about what the "coat" of a building looks like? Yes, it's about the curtain

- Curtain Wall Aluminum Veneer: The 'Gorgeous Coat' of Modern Architecture

Frequently asked questions

- Can the decorative effect of aluminum veneer be customized?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- What is the thermal expansion coefficient of aluminum veneer?

- Can aluminum veneer be used for building ceiling design?

- What impact does the surface treatment method of aluminum veneer have on its price?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

High quality ceiling carved aluminum veneer material selection

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-03 17:12:21

- Click:0

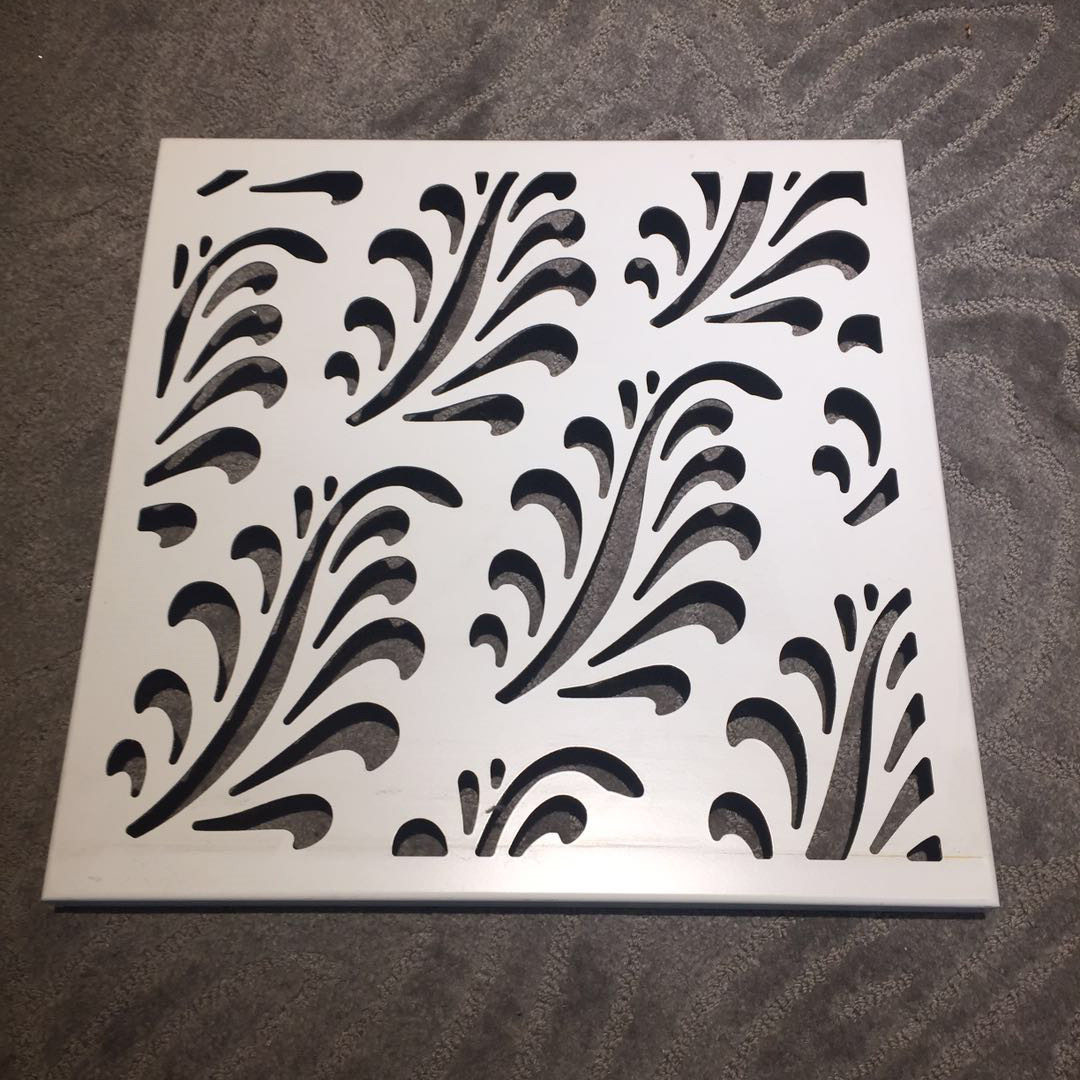

Ceiling carvingAluminum veneerIt is an exquisite building material with excellent carving effect, which can achieve various decorative effects. High quality ceiling carved aluminum veneer material is the key to producing high-quality products. This article will provide a detailed introduction to the selection of high-quality ceiling carved aluminum veneer materials.

1、 Raw material selection

1. Aluminum alloy sheet

The main raw material for ceiling carved aluminum veneer is aluminum alloy sheet, and it is necessary to choose high-quality raw materials. High quality aluminum alloy sheets have high strength and hardness, which can ensure the stability and durability of the product.

2. Coating materials

The surface of the ceiling carved aluminum veneer needs to be treated with spraying or anodizing to improve its aesthetics and anti-corrosion performance. It is necessary to choose high-quality coating materials to ensure the uniformity and durability of the coating.

3. Accessory materials

Various accessories such as rivets, screws, etc. are required for the installation of ceiling carved aluminum veneer. It is necessary to choose high-quality accessory materials to ensure the strength and durability of the accessories.

2、 Production process selection

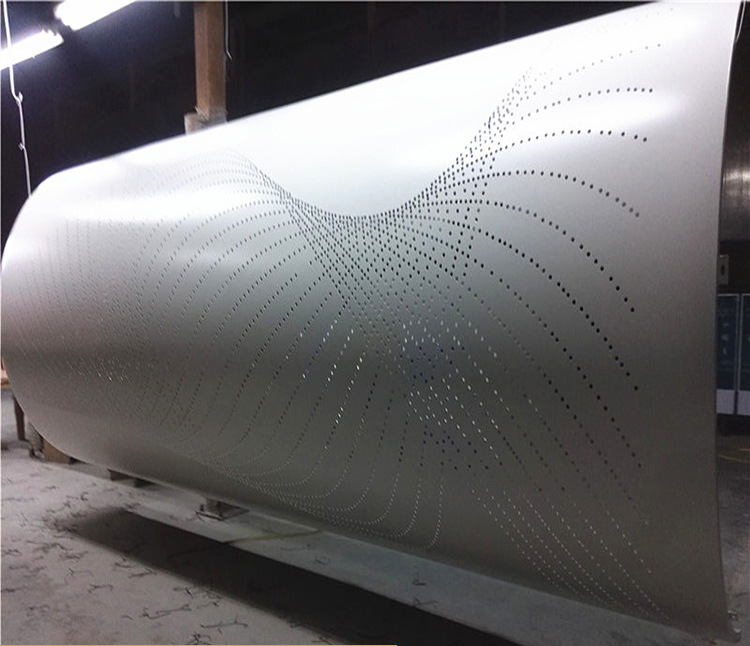

1. Punching process

Punching is one of the important processes for making ceiling carved aluminum veneer, which requires the selection of advanced punching equipment and process flow to ensure the quality and accuracy of punching. It is also necessary to perform surface treatment on the punched aluminum plate to improve its aesthetics and anti-corrosion performance.

2. Carving process

Carving is another important process for making ceiling carved aluminum veneer, which requires the selection of professional carving equipment and process flow to ensure the quality and accuracy of carving. It is also necessary to perform surface treatment on the carved aluminum plate to improve its aesthetics and anti-corrosion performance.

3、 Quality control

1. Raw material inspection

During the production process, strict inspection and screening of raw materials are required to ensure that their quality meets the requirements. For example, it is necessary to measure and test the thickness, hardness, etc. of aluminum alloy sheets to ensure the stability and durability of the product.

2. Production process control

In the production process, strict control and management of the production process are required to ensure the stability and consistency of product quality. For example, it is necessary to adjust and optimize the parameters of punching and engraving equipment to improve production efficiency and accuracy.

3. Finished product inspection

Before leaving the factory, strict inspection and testing are required to ensure that the product quality meets the requirements. For example, it is necessary to measure and test the surface flatness, color uniformity, etc. of the product to ensure its aesthetics and quality stability.

The selection of high-quality ceiling carved aluminum veneer material is the key to producing high-quality products. By selecting high-quality raw materials, advanced production processes, and strict quality control measures, we can produce more stable, beautiful, and durable ceiling carved aluminum veneer products.

Customer service QQ

Customer service QQ