Industry information

Company News

- Aluminum curtain wall: the fashionable choice for modern architecture

- Aluminum veneer curtain wall, the "fashionable coat" of modern architecture

- Aluminum veneer curtain wall, the new darling of architectural art

- Customized aluminum veneer, creating a new choice for personalized space!

- Aluminum curtain wall: the "fashionable coat" of modern architecture

Industry dynamics

- Aluminum curtain wall, the "green coat" of modern architecture

- Aluminum veneer enhances the value and attractiveness of buildings

- Aluminum veneer is cost-effective

- Aluminum veneer customization, creating a new trend of personalized space!

- Aluminum Curtain Wall: Aesthetic Revolution in Modern Architecture

Frequently asked questions

- Can the decorative effect of aluminum veneer be customized?

- What impact does the thickness of aluminum veneer have on architectural design?

- How does the customizability of aluminum veneer affect the appearance of buildings?

- What impact does the surface treatment method of aluminum veneer have on its price?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Carving process and quality assurance of 2.0mm aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-21 20:57:48

- Click:0

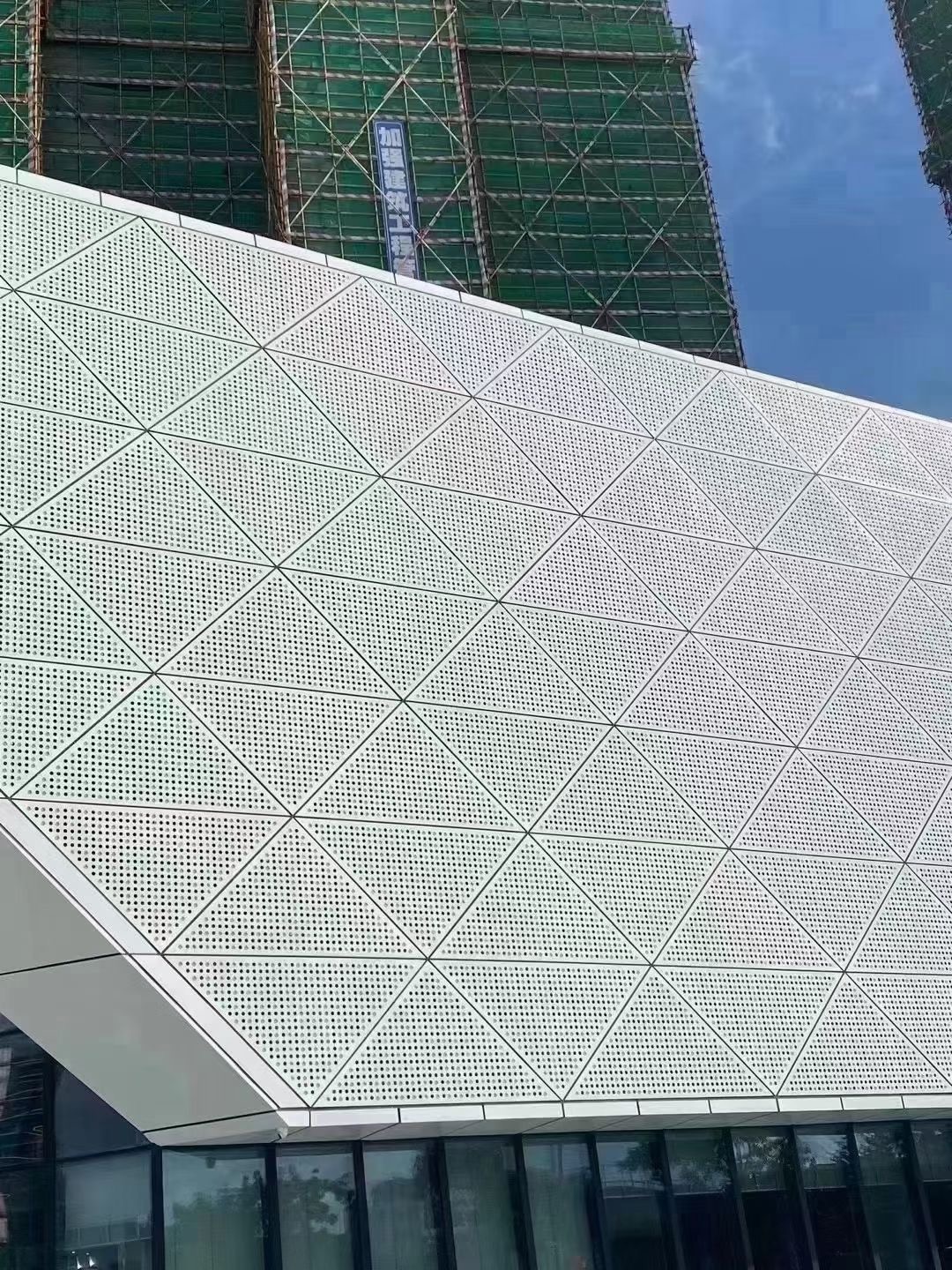

Carving 2.0mmAluminum veneerIt is a very popular modern architectural decoration material, and its unique design and production process can add unique charm to buildings. When choosing to carve 2.0mm aluminum veneer, in addition to paying attention to its design style and appearance, it is also necessary to pay attention to its craftsmanship and quality assurance. Below, we will provide a detailed introduction to the process and quality assurance of carving 2.0mm aluminum veneer.

1、 Process assurance

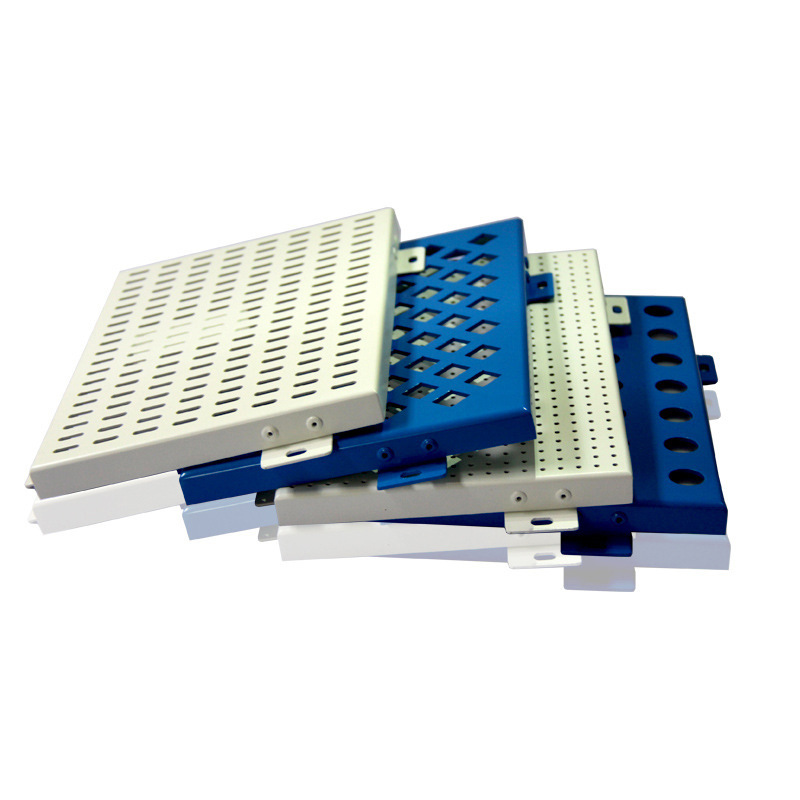

The production process of carving 2.0mm aluminum veneer requires multiple steps, including design, cutting, polishing, spraying, etc. In these processes, every step requires continuous improvement to ensure the quality and performance of the final product. Specifically, the process guarantee for carving 2.0mm aluminum veneer includes the following aspects:

1. Design assurance: Designers need to design according to the client's needs and requirements, and provide detailed design plans and material lists. In the design process, designers need to consider factors such as the size, shape, and color of aluminum veneer to ensure that the final product meets the customer's requirements.

2. Cutting guarantee: Cutting is one of the important processes for carving 2.0mm aluminum veneer production, which requires the use of high-precision cutting equipment for processing. During the cutting process, it is necessary to control the cutting speed and force to avoid deformation or damage to the aluminum veneer.

3. Polishing guarantee: Polishing is the final process of carving 2.0mm aluminum veneer, which can make the surface of the aluminum veneer smoother and smoother. During the polishing process, it is necessary to use professional polishing equipment and tools to ensure that the polishing effect meets expectations.

2、 Quality Assurance

The quality assurance of carving 2.0mm aluminum veneer is the responsibility that manufacturers must bear. Specifically, the quality assurance for carving 2.0mm aluminum veneer includes the following aspects:

1. Raw material guarantee: Manufacturers need to choose high-quality aluminum alloy raw materials for production to ensure the quality and performance of the final product.

2. Production process assurance: Manufacturers need to adopt advanced production processes and technologies to ensure that every step meets high quality requirements.

3. Testing guarantee: Manufacturers need to conduct strict testing and inspection on every 2.0mm carved aluminum veneer produced to ensure that it meets relevant quality standards and requirements.

The process and quality assurance of carving 2.0mm aluminum veneer are very important, as they directly affect the quality and performance of the product. When choosing to carve 2.0mm aluminum veneer, we need to pay attention to the manufacturer's strength and technical level, as well as understand their craftsmanship and quality assurance measures to ensure that the final selected product can meet our needs and requirements.

Customer service QQ

Customer service QQ