Industry information

Company News

- Aluminum Curtain Wall: An Elegant Choice in Modern Architecture

- Aluminum curtain wall, the fashionable coat of modern architecture

- Aluminum veneer: making buildings more sturdy and reliable

- Aluminum Curtain Wall: The Gorgeous Coat of Modern Architecture

- Aluminum veneer: the invisible star of industry

Industry dynamics

- Behind the good reputation of aluminum veneer

- How durable is the surface treatment of aluminum veneer?

- Aluminum veneer: making your building more environmentally friendly

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer construction process and technology

Frequently asked questions

- What is the color stability of aluminum veneer?

- Can the decorative effect of aluminum veneer be customized?

- What impact does the surface treatment method of aluminum veneer have on its price?

- Can the insulation function of aluminum veneer save energy?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Master the quality inspection process of aluminum veneer manufacturers

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-04 05:30:05

- Click:0

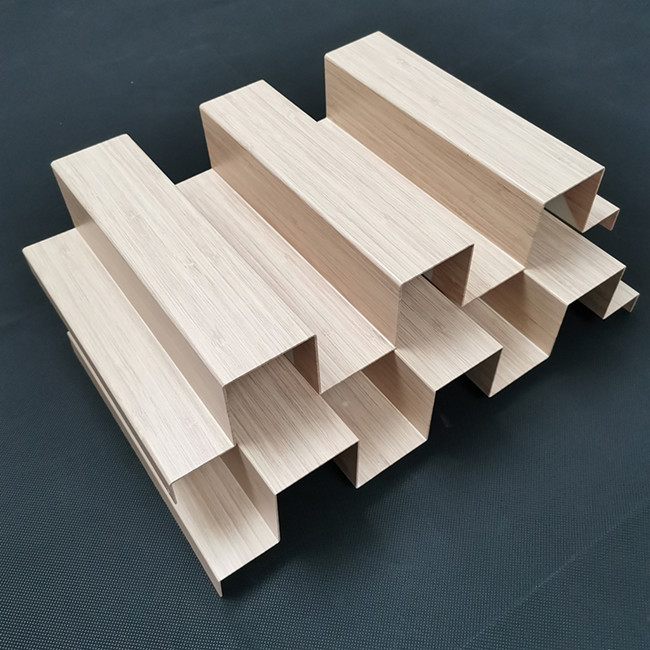

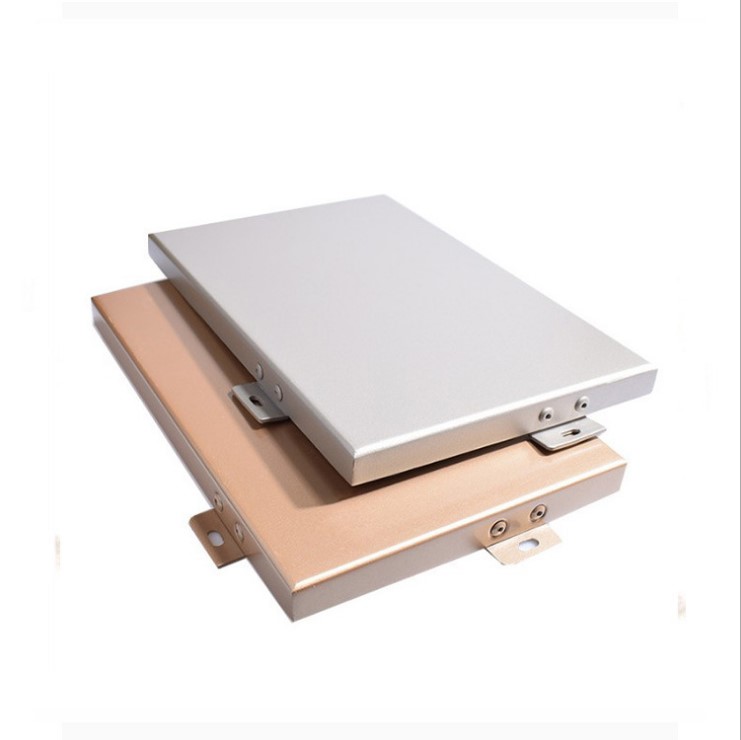

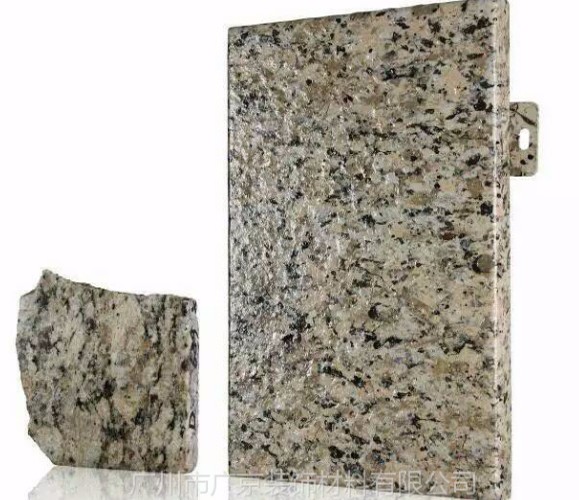

Aluminum veneerAs a new type of building material, its quality testing is an important guarantee for ensuring product quality and stability. High quality aluminum veneer manufacturers should pay attention to mastering the quality inspection process, establishing a sound quality management system and technical system, and improving the market competitiveness and differentiation advantages of their products. Below, we will grasp the quality inspection process of aluminum veneer manufacturers from multiple perspectives.

1、 Raw material testing

Raw material testing is one of the primary aspects of quality inspection for aluminum veneer manufacturers. High quality aluminum veneer manufacturers should conduct strict testing and screening of raw materials to ensure their quality and stability. By testing the physical properties, chemical composition, appearance, and other aspects of raw materials, we can understand their quality and provide a basis for subsequent production.

2、 Production process inspection

Production process inspection is one of the key links in the quality inspection of aluminum veneer manufacturers. High quality aluminum veneer manufacturers should establish a comprehensive production process monitoring system, monitor and record key parameters in real-time during the production process, promptly identify and solve problems in the production process, and ensure product quality and stability. By inspecting and managing the equipment, processes, personnel, and other aspects of the production line, production efficiency and quality stability can be improved.

3、 Finished product testing

Finished product testing is one of the important aspects of quality inspection for aluminum veneer manufacturers. High quality aluminum veneer manufacturers should conduct comprehensive testing and testing on finished products, including physical properties, chemical composition, appearance, etc., to ensure product quality and stability. By collaborating with authoritative institutions and adopting internationally recognized standards and methods for testing and inspection, we can enhance the market competitiveness and differentiation advantages of our products.

4、 After sales service

After sales service is one of the important guarantees for quality inspection of aluminum veneer manufacturers. High quality aluminum veneer manufacturers should provide comprehensive after-sales service and technical support, and be able to promptly solve customer problems and needs during product use. At the same time, attention should be paid to communication and interaction with customers, understanding their feedback and suggestions, adjusting product and service strategies in a timely manner, and improving customer satisfaction and loyalty.

5、 Summary

The above is a detailed introduction to mastering the quality inspection process of aluminum veneer manufacturers. Raw material testing, production process testing, finished product testing, and after-sales service are key factors affecting the quality testing of aluminum veneer manufacturers. In the future, with the continuous advancement of technology and the development of innovation, we believe that there will be more outstanding enterprises emerging in the aluminum veneer industry, bringing people a better living experience and making greater contributions to environmental protection.

Customer service QQ

Customer service QQ