Industry information

Company News

- Aluminum curtain wall: the fashionable choice for modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum curtain wall: the beauty of architecture, the soul of innovation

- Aluminum veneer: the new aesthetic favorite of modern architecture

- The new trend of aluminum veneer, the new darling of fashionable architecture!

Industry dynamics

- Curtain wall aluminum veneer: a perfect fusion of architectural aesthetics and practicality

- Aluminum curtain wall, the "green coat" of modern architecture

- Aluminum veneer: the 'invisible hero' of modern architecture

- How much do you know about curtain wall aluminum veneer: the "fashionable coat" of architecture?

- Curtain wall aluminum veneer: a fashionable tool for creating modern architecture

Frequently asked questions

- How does the customizability of aluminum veneer affect the appearance of buildings?

- Will the use of aluminum veneer affect the ventilation effect of buildings?

- Can the decorative effect of aluminum veneer be customized?

- Can aluminum veneer be used for building ceiling design?

- What impact does the surface treatment method of aluminum veneer have on its price?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Material selection and environmental performance of wood grain 1.5mm aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-22 20:32:56

- Click:0

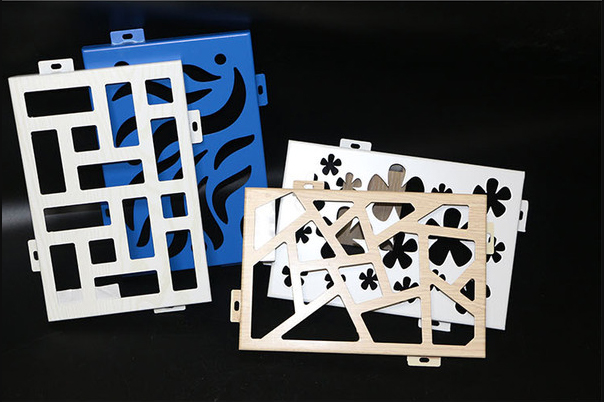

Wood grain 1.5mmAluminum veneerIt is a common building material that presents a wood like texture on its surface, with advantages such as aesthetics and environmental friendliness. When choosing the material of wood grain 1.5mm aluminum veneer, multiple factors need to be considered, such as strength, durability, fire resistance, environmental performance, etc. Below, we will provide a detailed introduction to the material selection and environmental performance of wood grain 1.5mm aluminum veneer.

1、 Material selection

1. Aluminum alloy material

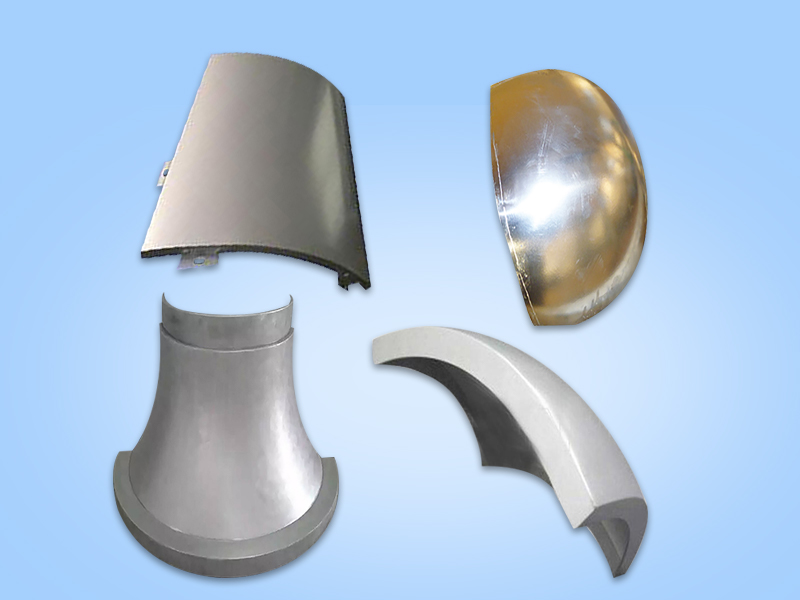

The main raw material for wood grain 1.5mm aluminum veneer is aluminum alloy material, which has high strength and stiffness, and is not easily deformed or damaged. Aluminum alloy materials also have good corrosion resistance and oxidation resistance, with a long service life. When choosing the material of 1.5mm wood grain aluminum veneer, priority should be given to aluminum alloy materials.

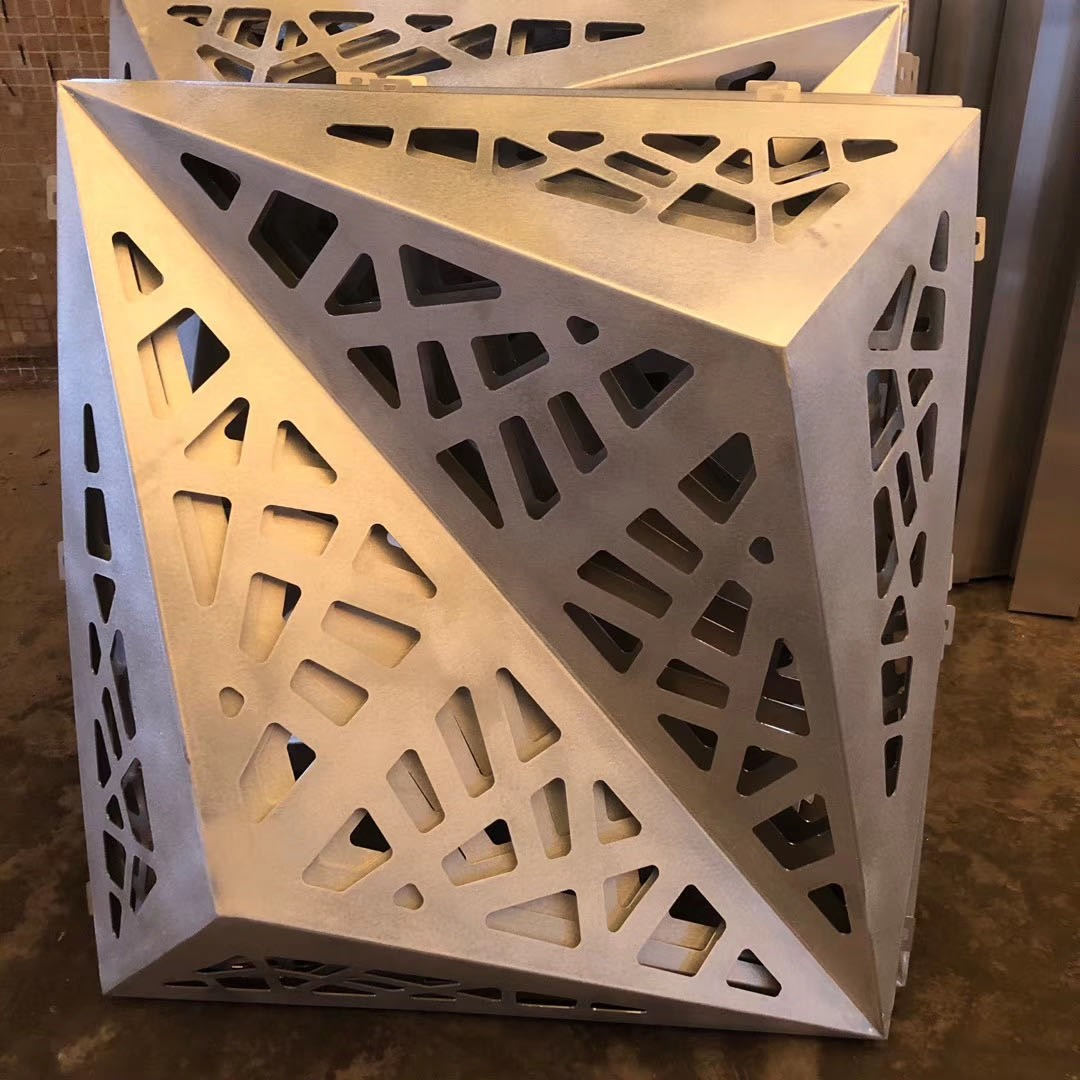

1. Surface treatment process

In addition to aluminum alloy materials, the surface treatment process of wood grain 1.5mm aluminum veneer is also very important. Common surface treatment processes include anodizing, electrophoretic coating, powder coating, etc. Anodizing process can form an oxide film on the surface of aluminum alloy, improving its wear resistance and corrosion resistance; Electrophoretic coating and powder coating processes can provide a more uniform and aesthetically pleasing surface effect.

2、 Environmental performance

1. Non toxic and harmless

The main raw material for 1.5mm wood grain aluminum veneer is aluminum alloy, which is a non-toxic and harmless metal element. The wood grain 1.5mm aluminum veneer itself does not pose any harm to human health.

1. Recyclable and reusable

The material of wood grain 1.5mm aluminum veneer can be recycled, reducing environmental pollution and resource waste. For example, discarded wood grain 1.5mm aluminum veneer can be remade into new aluminum or other products through melting.

1. Compliant with environmental standards

During the production process, wood grain 1.5mm aluminum veneer needs to comply with relevant environmental standards and regulations, such as ISO 9001 quality management system, ISO 14001 environmental management system, etc. Strict supervision and management of the production process are also necessary to ensure compliance with environmental requirements.

When choosing the material of 1.5mm wood grain aluminum veneer, priority should be given to aluminum alloy materials and attention should be paid to their surface treatment processes. Attention should also be paid to its environmental performance, including non toxicity, harmlessness, recyclability, and other aspects. Only in this way can we ensure the safety, environmental protection, and sustainable development of the selected materials.

Customer service QQ

Customer service QQ