Industry information

Company News

- Aluminum veneer: the hero behind architectural aesthetics

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum curtain wall: the aesthetic code of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Curtain wall aluminum veneer: a fashionable choice for creating modern architecture!

Industry dynamics

- Aluminum veneer: the fashionable choice for modern architecture

- Aluminum veneer: outstanding performance in weather resistance and durability

- How to choose suitable perforated aluminum veneer for exterior walls

- Aluminum curtain wall: the "fashionable coat" of modern architecture

- The charm of aluminum veneer: not just decoration, but also the art of life

Frequently asked questions

- What is the color stability of aluminum veneer?

- What is the thermal expansion coefficient of aluminum veneer?

- How does the customizability of aluminum veneer affect the appearance of buildings?

- What impact does the thickness of aluminum veneer have on architectural design?

- Can aluminum veneer be used for building ceiling design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

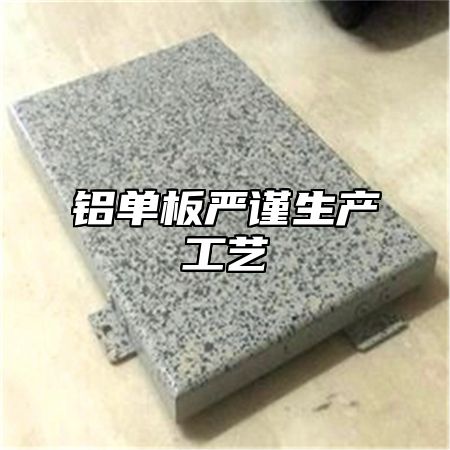

Rigorous production process for aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-25 04:14:23

- Click:0

Aluminum veneerAs a new type of building material, its production process has a significant impact on product quality and performance. The rigorous production process of aluminum veneer will be introduced in detail below.

1、 Raw material inspection

Before production, strict inspection and screening of the raw materials for aluminum veneer are required to ensure that they meet national standards and industry requirements. The inspection content includes the chemical composition, mechanical properties, surface quality, etc. of aluminum alloy sheets. Only when the raw materials meet the requirements can the high quality of aluminum veneer products be guaranteed.

2、 Cutting and processing

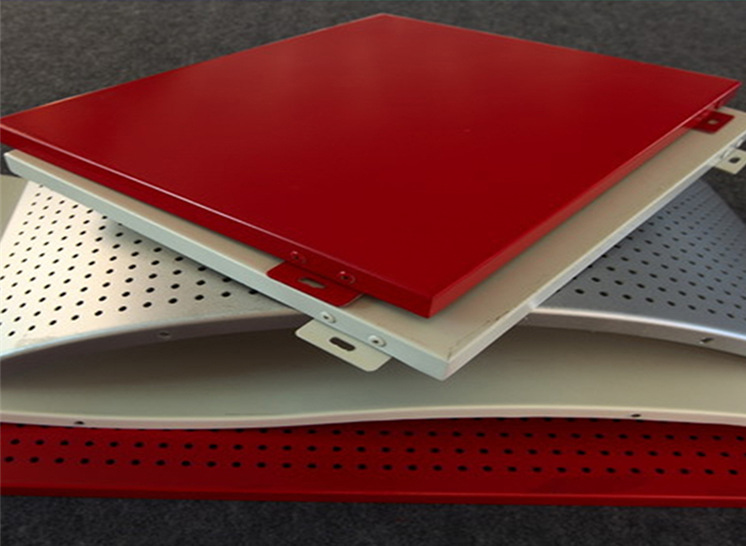

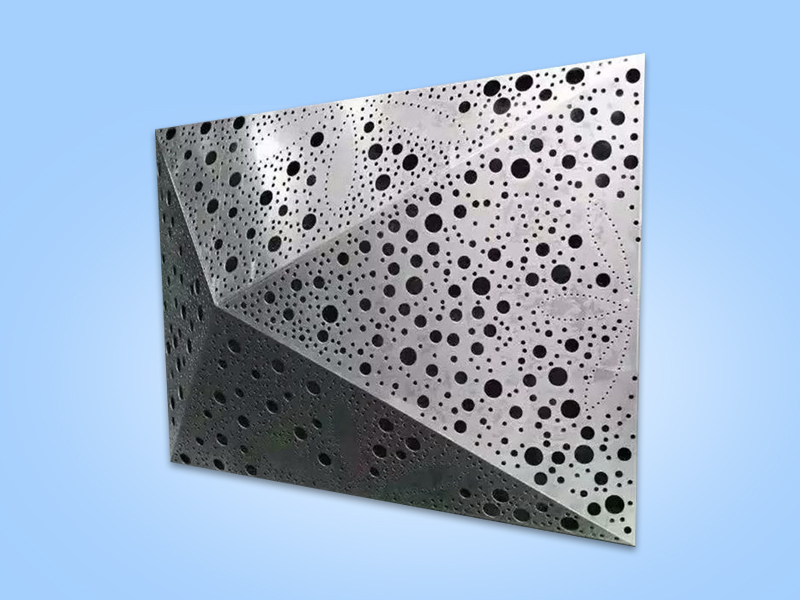

Cut and process aluminum alloy sheets according to design requirements, including processes such as opening, cutting, and punching. The quality of cutting processing directly affects the dimensional accuracy and surface smoothness of aluminum veneer products. During the cutting process, it is necessary to strictly control the degree of tool wear and cutting speed to ensure cutting quality.

3、 Welding processing

Welding processing of aluminum alloy sheets, including spot welding, pressure welding, seam welding, and other processes. The quality of welding processing directly affects the strength and durability of aluminum veneer products. During the welding process, it is necessary to strictly control the welding current, voltage, and welding speed to ensure welding quality. It is also necessary to inspect and test the welded joints to ensure that the welding quality meets the standard requirements.

4、 Grinding and processing

Polish the aluminum veneer products after welding processing to make their surface smoother and improve the appearance quality of the products. During the polishing process, it is necessary to use suitable grinding wheels and abrasives to control the grinding speed and force, in order to avoid scratches or unevenness on the surface of the aluminum veneer.

5、 Surface treatment

Surface treatment of aluminum veneer products, including spraying, roller coating, electrophoretic coating and other processes. The quality of surface treatment directly affects the corrosion resistance and decorative properties of aluminum veneer products. During the surface treatment process, it is necessary to select appropriate coatings and process parameters, control the thickness and uniformity of the coating, to ensure that the surface quality meets the standard requirements.

6、 Packaging and transportation

Packaging and transportation of aluminum veneer products that have undergone surface treatment to ensure that the products are not damaged during transportation. During the packaging process, it is necessary to choose appropriate packaging materials and methods to prevent aluminum veneer products from being squeezed or bumped. It is also necessary to label and record the packaging for traceability and management.

The rigorous production process of aluminum veneer mainly includes multiple links such as raw material inspection, cutting processing, welding processing, polishing processing, surface treatment, and packaging and transportation. Each stage has a significant impact on the quality and performance of aluminum veneer products. Aluminum veneer enterprises should pay attention to the management and service of production processes, improve production efficiency and product quality. Only by deeply understanding the characteristics and requirements of production processes can the aluminum veneer industry thrive and prosper in the future.

Customer service QQ

Customer service QQ