Industry information

Company News

- Aluminum veneer curtain wall, the fashionable coat of architecture

- Aluminum veneer: the new darling of architectural aesthetics, how to overturn traditional building materials?

- Aluminum curtain wall: the "fashionable coat" of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer customization, creating an artistic journey of personalized space

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space!

- Analysis of Characteristics and Application Fields of Hyperbolic Aluminum Single Panel Curtain Wall

- Aluminum veneer: a delicate interpretation of architectural aesthetics

- Analysis of price trend of aluminum veneer

- Curtain wall aluminum veneer, the secret of light luxury in architectural aesthetics

Frequently asked questions

- What is the thermal expansion coefficient of aluminum veneer?

- Will the use of aluminum veneer affect the ventilation effect of buildings?

- How does the customizability of aluminum veneer affect the appearance of buildings?

- Can the decorative effect of aluminum veneer be customized?

- What impact does the thickness of aluminum veneer have on architectural design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

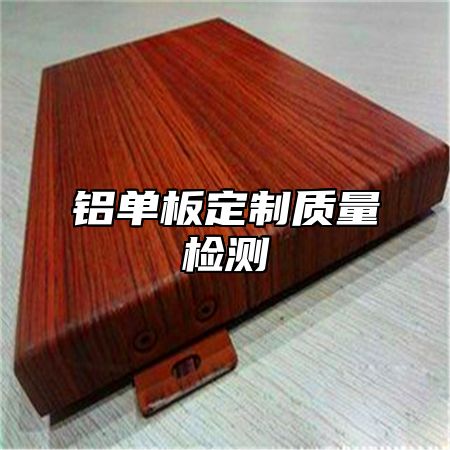

Customized quality inspection of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-24 20:04:24

- Click:0

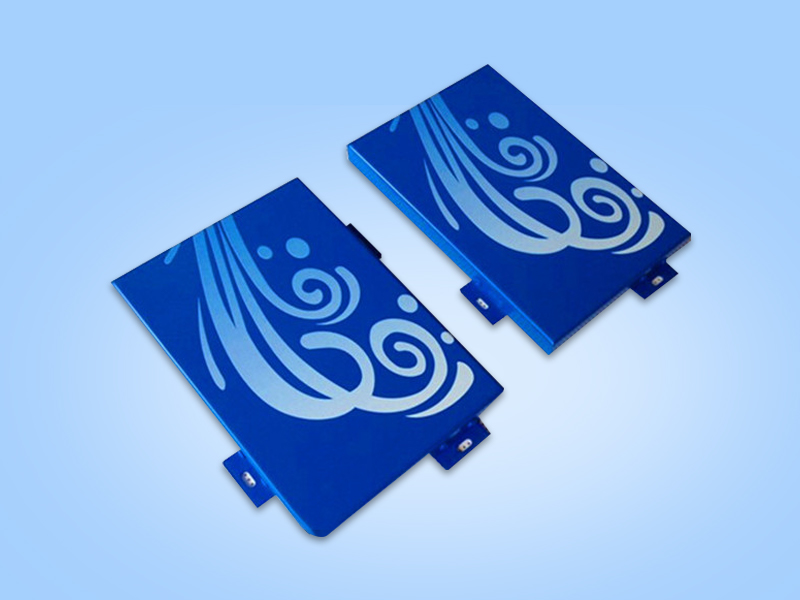

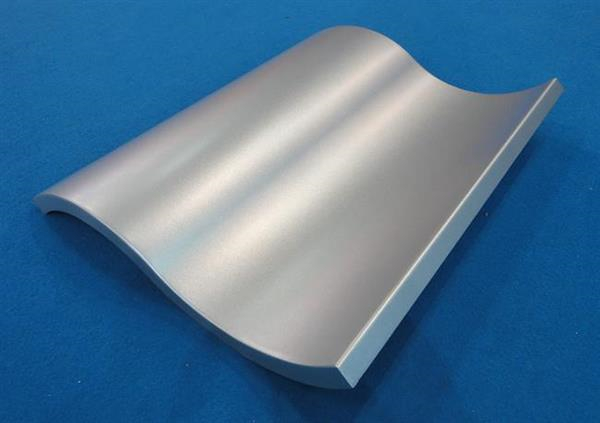

Aluminum veneerCustomization, as a new type of building decoration material, its quality inspection is also a very important part. When customizing aluminum veneer, it is necessary to conduct comprehensive testing and evaluation of the product to ensure product quality and safety. Below, we will provide a detailed introduction to the quality inspection of customized aluminum veneer.

1、 Appearance quality inspection

The appearance quality of aluminum veneer is an important factor affecting its decorative effect and durability. When conducting quality inspection, it is necessary to comprehensively check and evaluate the surface flatness, color, texture, and other aspects of aluminum veneer to ensure that it meets the design requirements and standards. It is also necessary to inspect the edges and corners of the aluminum veneer to avoid problems such as cracks and deformation.

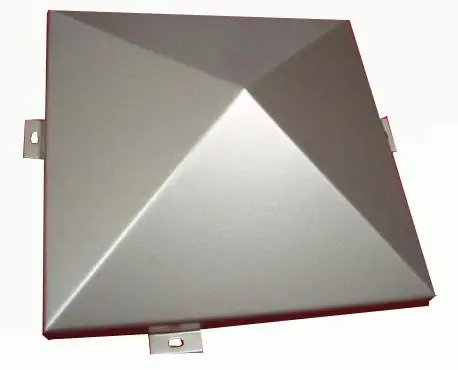

2、 Strength and hardness testing

The strength and hardness of aluminum veneer are also important factors affecting its service life and safety. When conducting quality inspection, it is necessary to conduct comprehensive testing and evaluation of the strength and hardness of aluminum veneer to ensure that it meets design requirements and standards. For example, methods such as tensile testing and bending testing can be used to test the tensile strength, yield strength, elongation, and other indicators of aluminum veneer; Hardness testers and other equipment can be used to test the Rockwell hardness, Brinell hardness, and other indicators of aluminum veneer.

3、 Coating quality inspection

The coating quality of aluminum veneer is also an important factor affecting its decorative effect and durability. When conducting quality inspection, it is necessary to comprehensively check and evaluate the coating thickness, uniformity, adhesion, and other aspects of aluminum veneer to ensure that it meets the design requirements and standards. For example, optical microscopes and other equipment can be used to observe the thickness and uniformity of coatings; Methods such as grid tests can be used to test the adhesion and impact resistance of coatings.

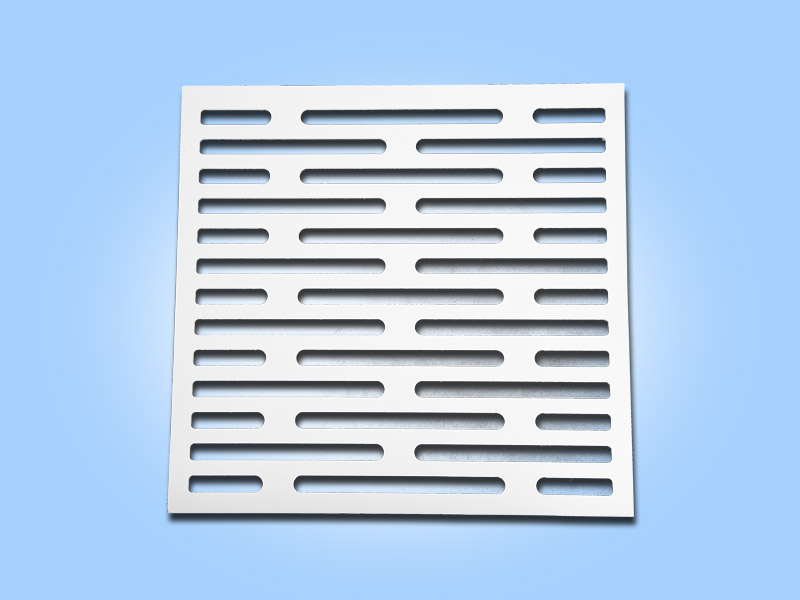

4、 Dimensional accuracy testing

The dimensional accuracy of aluminum veneer is also an important factor affecting its decorative effect. When conducting quality inspection, it is necessary to comprehensively measure and evaluate the length, width, thickness, and other aspects of aluminum veneer to ensure that it meets design requirements and standards. For example, high-precision measuring instruments can be used to measure and calibrate the dimensions of aluminum veneer; Comparative methods can be used to compare and analyze the dimensional accuracy of products from different batches.

5、 Environmental performance testing

The environmental performance of aluminum veneer is also an increasingly concerned issue. When conducting quality inspections, it is necessary to conduct comprehensive testing and evaluation of the environmental performance of aluminum veneer to ensure that it meets relevant national standards and requirements. For example, gas chromatographs and other equipment can be used to test whether aluminum veneers contain harmful substances; Microbial testing and other methods can be used to detect indicators such as heavy metal content in aluminum veneer.

The quality inspection of customized aluminum veneer is a very important part. In the actual operation process, it is necessary to conduct reasonable quality testing according to the actual situation to ensure product quality and safety. We also need to consider future development trends and environmental protection and energy conservation issues, actively respond to national policies and industry standards, and promote the healthy development of the aluminum veneer customization industry.

Customer service QQ

Customer service QQ