Industry information

Company News

- Aluminum curtain wall is not just a "face saving project"!

- Aluminum veneer: the "green guardian" of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: understated luxury in modern architecture

- The Charm and Changes of Aluminum Veneer: The Transformation from Building Exterior Walls to Artworks

Industry dynamics

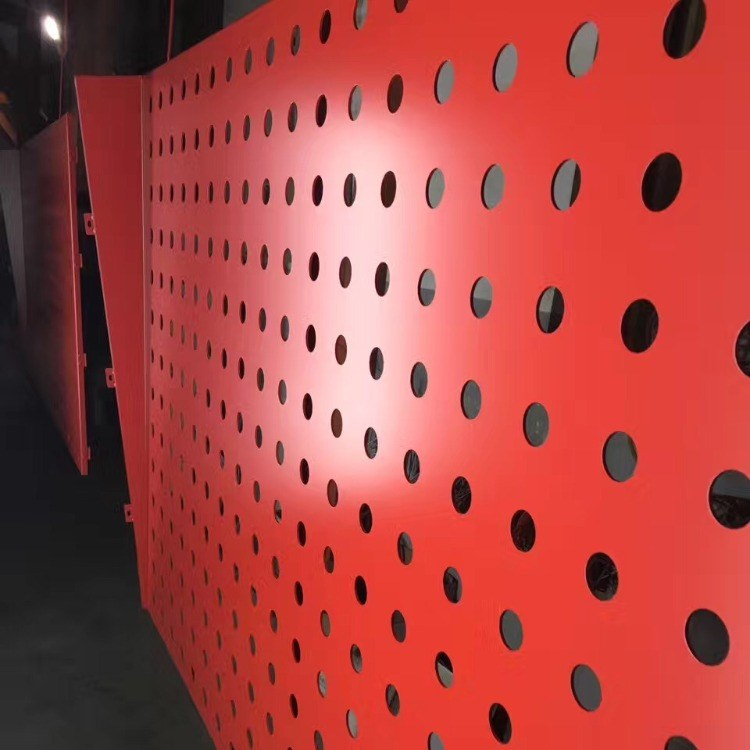

- Exquisite punched and carved aluminum veneer showcases high-quality craftsmanship

- The market trend of customized aluminum veneer is constantly expanding, and there is a growing consumer demand

- Aluminum veneer is the new favorite of charming curtain walls. How can aluminum veneer shape the beauty of modern architecture?

- Customize aluminum veneer to create personalized spatial aesthetics

- Aluminum veneer creates a fashionable and modern architectural appearance

Frequently asked questions

- What is the thermal expansion coefficient of aluminum veneer?

- How does the customizability of aluminum veneer affect the appearance of buildings?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- What impact does the thickness of aluminum veneer have on architectural design?

- Can the insulation function of aluminum veneer save energy?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the installation tools for aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-08 17:20:48

- Click:0

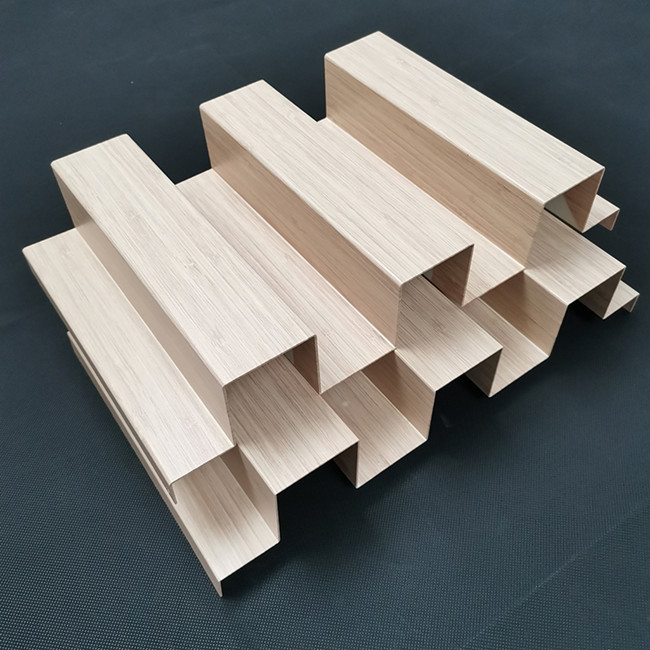

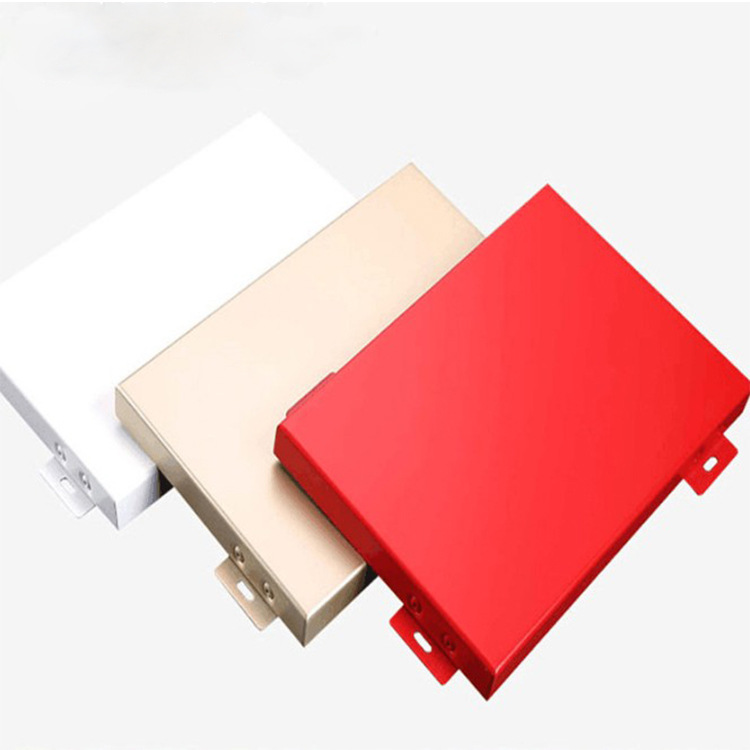

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and its installation quality is one of the important factors affecting its service life and safety. The installation of aluminum veneer requires the use of some professional tools. The following will provide a detailed introduction to the installation tools and their functions for aluminum veneer.

1. Hand drill

Hand drill is one of the most basic tools in aluminum veneer installation, mainly used for drilling holes in walls or ceilings. Generally speaking, the higher the power of the electric drill, the faster the drilling speed. However, it is important to maintain stability when using the electric drill to avoid displacement or damage to the wall.

1. Electric angle grinder

Electric angle grinder is mainly used for grinding and trimming the edges of aluminum veneer to ensure smooth and flat connections between the aluminum veneer and walls or ceilings. Generally speaking, the higher the power of an electric angle grinder, the better the polishing effect. However, it is important to maintain a stable handheld posture when using an electric angle grinder to avoid accidental injuries.

1. Steel ruler

Steel ruler is one of the essential tools in the installation of aluminum veneer, mainly used to measure the length and width of aluminum veneer. Generally speaking, the higher the accuracy of a steel ruler, the more accurate the measurement results will be. However, it is important to note that when using a steel ruler, it should be kept horizontal and vertical to avoid errors.

1. Angular protractor

The protractor is mainly used for angle measurement and adjustment at the edge of aluminum veneer to ensure that the angle between the aluminum veneer and the wall or ceiling meets the requirements. Generally speaking, the higher the accuracy of the protractor, the more accurate the measurement results will be. However, it is important to maintain a stable and accurate handheld posture when using the protractor to avoid errors.

1. Cutting machine

The cutting machine is mainly used for cutting and processing aluminum veneer to meet different installation requirements. Generally speaking, the faster the cutting speed of a cutting machine, the better the cutting effect. However, it is important to maintain a stable handheld posture when using the cutting machine to avoid accidental injuries.

The installation of aluminum veneer requires the use of various tools such as handheld drills, electric angle grinders, steel rulers, protractors, and cutting machines. Enterprises should choose appropriate tools based on actual needs and strictly follow operating procedures for operation and maintenance to ensure product quality and safety performance.

Customer service QQ

Customer service QQ