Industry information

Company News

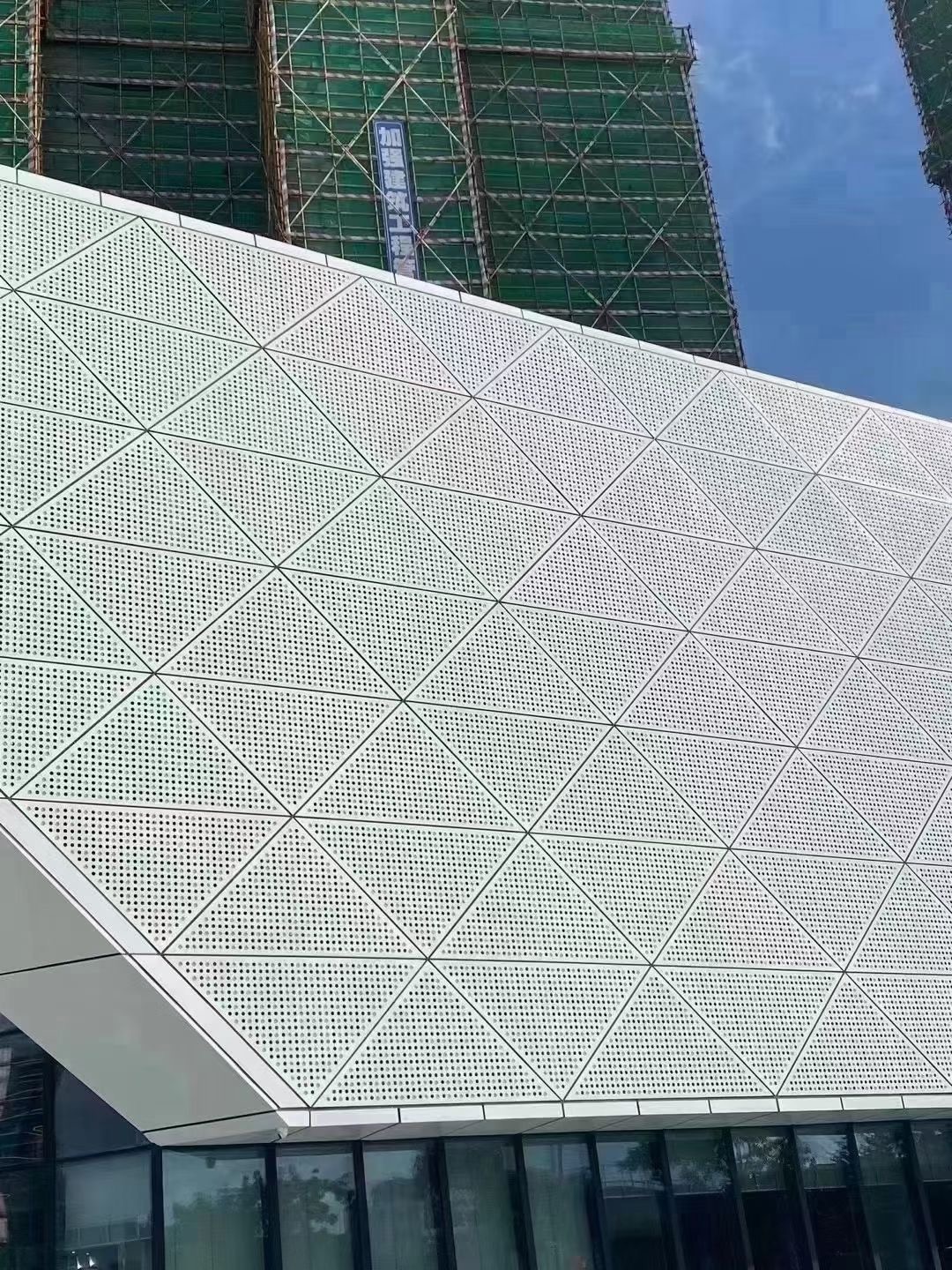

- Aluminum veneer: the fashionable choice for modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- How much do you know about aluminum curtain walls: the fashionable outerwear of modern architecture?

Industry dynamics

- Personalized customization of aluminum veneer design style!

- Aluminum veneer price - market research and data analysis

- Curtain wall aluminum veneer: creating a new style of modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space!

Frequently asked questions

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- What impact does the thickness of aluminum veneer have on architectural design?

- Can aluminum veneer be used for building ceiling design?

- How does the customizability of aluminum veneer affect the appearance of buildings?

- Will the use of aluminum veneer affect the ventilation effect of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Unveiling the surface treatment technology of aluminum veneer!

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 3, 2025 21:33:26

- Click:0

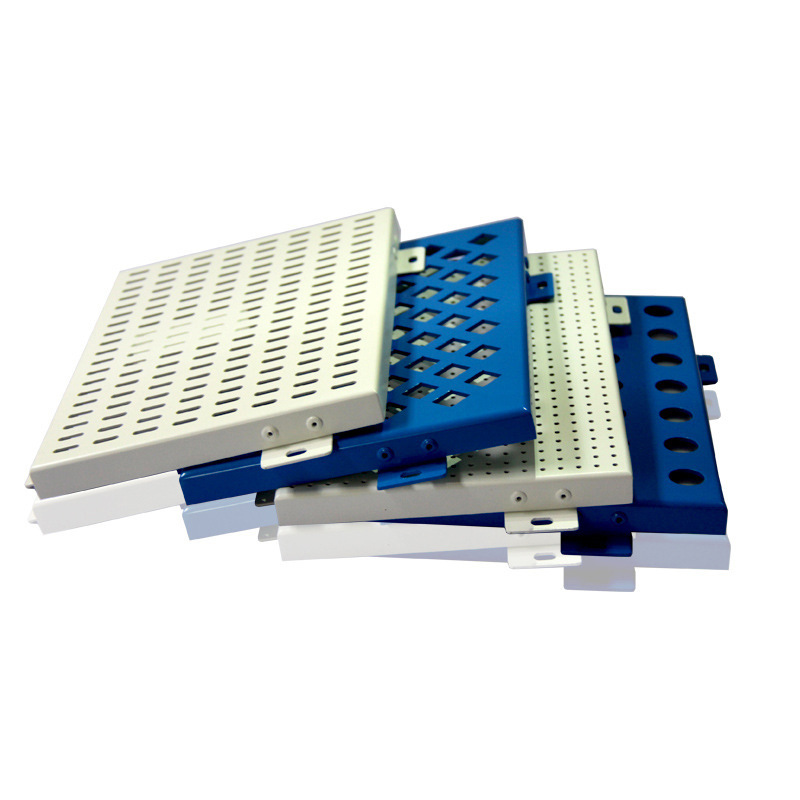

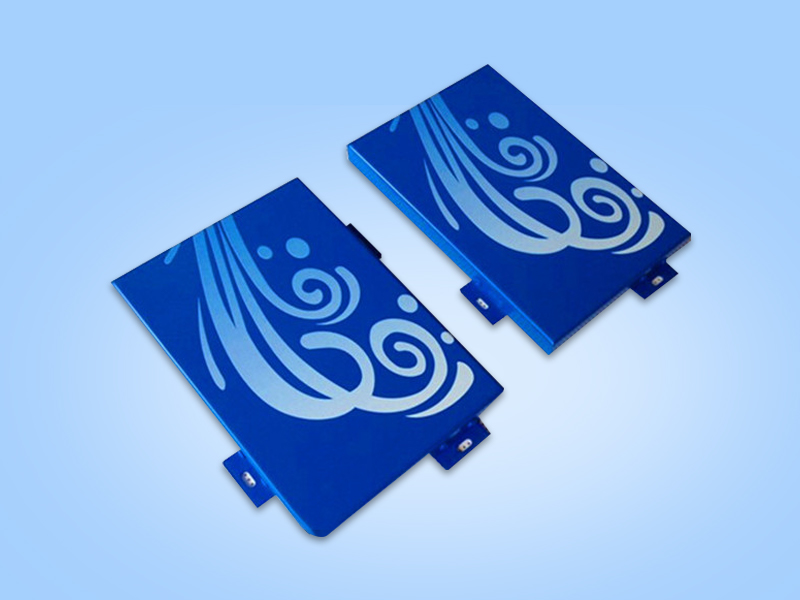

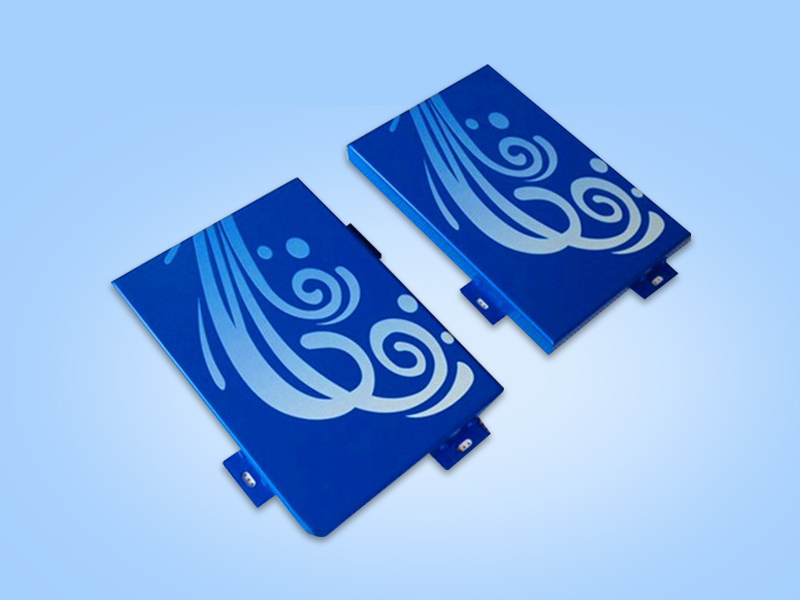

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, and corrosion resistance. The surface treatment technology of aluminum veneer is one of the important factors affecting its performance and aesthetics. This article will reveal the surface treatment technology of aluminum veneer from the following aspects.

1、 Anodizing treatment

Anodizing treatment is one of the main methods for surface treatment of aluminum veneer. This method forms an oxide film on the surface of aluminum veneer by applying current to the surface of the aluminum veneer. This oxide film can protect the surface of aluminum veneer from corrosion and wear, while also improving its corrosion resistance and hardness.

2、 Electrophoretic coating treatment

Electrophoretic coating treatment is an advanced surface treatment method for aluminum veneer. This method applies an electric field on the surface of aluminum veneer to make the coating particles charged and deposited on the surface of the aluminum veneer. This method can achieve characteristics such as uniform coating, bright colors, and strong corrosion resistance.

3、 Spray treatment

Spray coating treatment is a common surface treatment method for aluminum veneer. This method uses a spray gun to spray paint onto the surface of aluminum veneer, forming a uniform coating layer. This method can achieve rich colors and strong decorative features, but requires high technical and equipment support.

4、 Wire drawing processing

Wire drawing treatment is a relatively special surface treatment method for aluminum veneer. This method uses mechanical equipment to stretch the surface of aluminum veneer, creating a unique texture effect on its surface. This method can achieve strong decoration and good texture, but it requires high technical and equipment support.

5、 Polishing treatment

Polishing treatment is a common surface treatment method for aluminum veneer. This method uses mechanical equipment to polish the surface of aluminum veneer, resulting in a smooth and shiny appearance. This method can achieve strong decoration and good texture, but it requires high technical and equipment support.

6、 Summary

The surface treatment techniques for aluminum veneer include various methods such as anodizing, electrophoretic coating, spray coating, wire drawing, and polishing. These methods can meet the needs of different occasions and improve the performance and aesthetics of aluminum veneer. Enterprises should choose appropriate surface treatment technologies based on actual needs to improve product quality and competitiveness.

Customer service QQ

Customer service QQ