Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum curtain wall: the new darling of modern architecture, revealing its charm!

- Aluminum veneer: the 'invisible star' in modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer customization, creating an exclusive personalized space

Industry dynamics

- Characteristics and application range of 2.0mm aluminum veneer for ceiling

- What is the radiation protection performance of aluminum veneer?

- Stainless steel punched aluminum veneer material

- What is the seismic performance of aluminum veneer?

- Curtain wall aluminum veneer, the "fashionable coat" of architecture

Frequently asked questions

- Will the use of aluminum veneer affect the ventilation effect of buildings?

- What is the color stability of aluminum veneer?

- Can the decorative effect of aluminum veneer be customized?

- What impact does the thickness of aluminum veneer have on architectural design?

- What is the thermal expansion coefficient of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Exquisite craftsmanship in the production of carved aluminum veneer for door heads

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-02 07:08:36

- Click:0

The storefront is the facade of a building, which is not only an important component of the building, but also has the function of beautifying the building and protecting its structure. In the decoration of the storefront, carvingAluminum veneerIt is one of the commonly used materials, especially the exquisitely crafted carved aluminum veneer, which can showcase its excellent quality and manufacturing process. How to use exquisite carved aluminum veneer to create high-quality door heads?

1. Strictly control the selection of materials

Exquisite carved aluminum veneer requires the use of high-quality raw materials. Designers need to select materials based on the client's needs and the characteristics of the building. Here are some common material selection schemes:

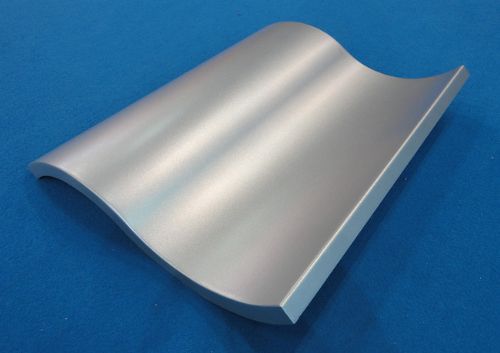

(1) Aluminum alloy sheet: Aluminum alloy has good strength and corrosion resistance, suitable for outdoor environments.

(2) Stainless steel sheet: Stainless steel has a high-end and atmospheric feel, suitable for high-end commercial places.

(3) Glass sheet: Glass has good transparency and texture, suitable for modern minimalist style buildings.

1. Fine design and production

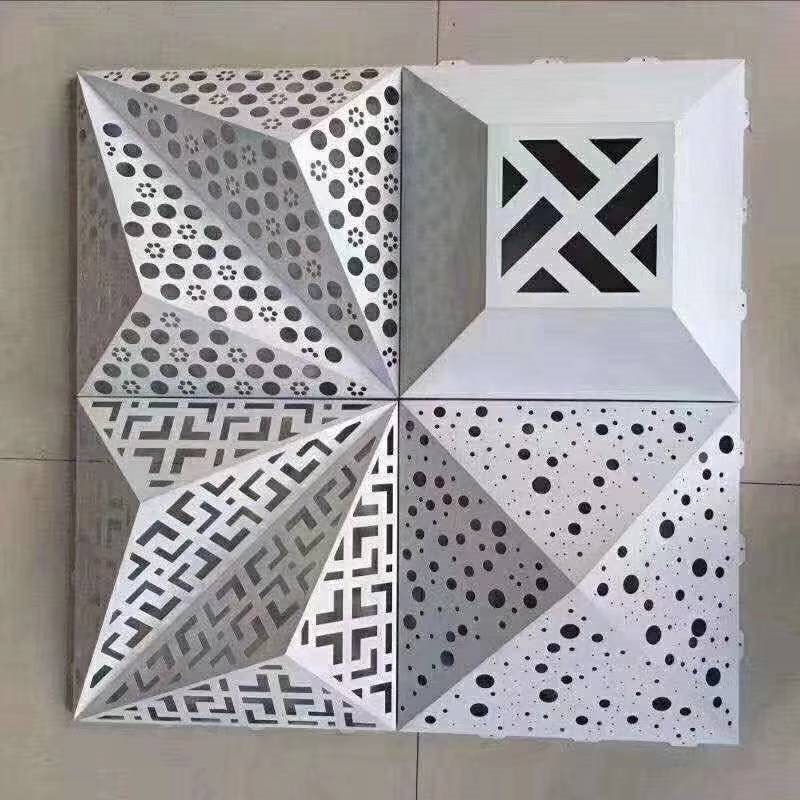

The design of carved aluminum veneer requires multiple modifications and improvements to ensure that the final effect meets the customer's requirements. Designers need to create creative designs based on the client's needs and the characteristics of the building, and make multiple modifications and improvements. Here are some common design and production processes:

(1) Preliminary Design: The designer will conduct a preliminary design based on the client's needs and the characteristics of the building, including patterns, shapes, sizes, etc.

(2) Refined design: Designers will refine and improve the preliminary design, including pattern details, color matching, etc.

(3) Sample production: Designers will create samples based on the refined design for customers to confirm and provide feedback.

(4) Production and manufacturing: Once the customer confirms the sample, production and manufacturing can begin. In the production and manufacturing process, it is necessary to strictly control every link to ensure that the final product meets high-quality standards.

1. Strict quality control

Exquisite carved aluminum veneer requires strict quality control to ensure its quality and stability. Here are some common quality control measures:

(1) Raw material inspection: Before production and manufacturing, it is necessary to inspect the raw materials to ensure that they meet the requirements.

(2) Production process inspection: In the production and manufacturing process, it is necessary to inspect each process to ensure the quality and stability of the product.

(3) Finished product inspection: After the completion of finished product production, comprehensive inspection and testing are required to ensure that the product meets customer requirements and standards.

1. Strict and standardized installation and construction

Customer service QQ

Customer service QQ