Industry information

Company News

- Aluminum veneer: an invisible star in the construction industry

- Curtain wall aluminum veneer: a fashionable outerwear for modern architecture

- Curtain wall aluminum veneer: a fashionable outerwear for modern architecture

- Aluminum curtain wall: the "fashionable coat" of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Aluminum veneer manufacturer's product research and development capability

- Engineering carved aluminum veneer makes buildings more artistic and tasteful

- Aluminum veneer's UV resistance

- Is the maintenance requirement for aluminum veneer high?

- Innovative Technology and Materials for Fluorocarbon Aluminum Honeycomb Panel Furniture Industry

Frequently asked questions

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- Can aluminum veneer be used for building ceiling design?

- What is the thermal expansion coefficient of aluminum veneer?

- Will the use of aluminum veneer affect the ventilation effect of buildings?

- Can the decorative effect of aluminum veneer be customized?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

High end design aluminum veneer manufacturing

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 2, 2025 03:53:28

- Click:0

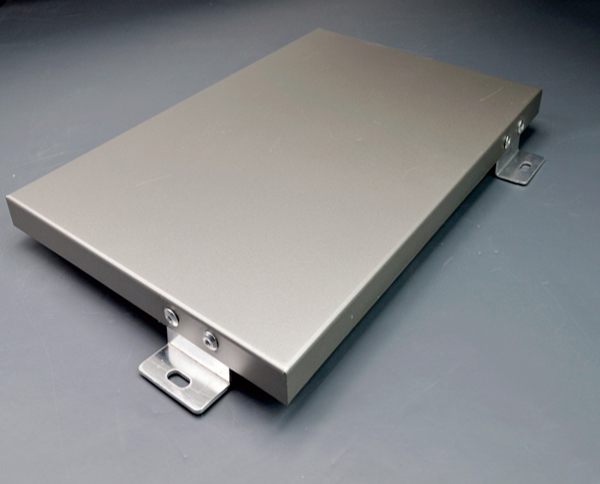

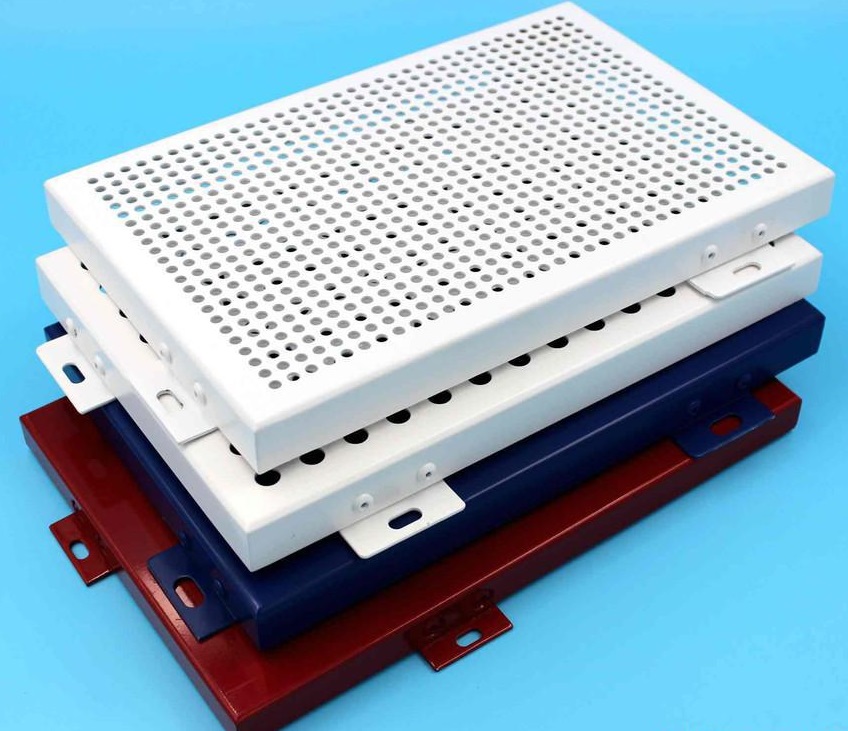

High end designAluminum veneerManufacturing is a manufacturing process with special techniques and processes that can provide aluminum veneer with a more beautiful, practical, and durable appearance and performance. High end shaped aluminum veneer manufacturing has been widely used in fields such as architecture and decoration. This article will provide a detailed introduction to the process and technology of manufacturing high-end shaped aluminum veneers.

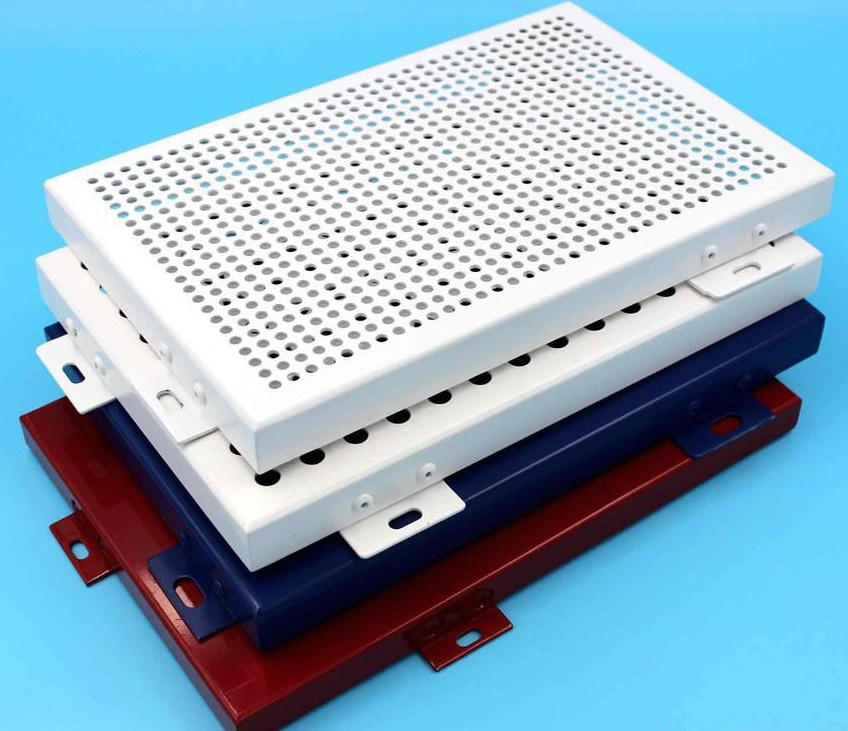

High end aluminum veneer manufacturing requires the use of high-quality raw materials, such as high-strength aluminum alloys, polyester resins, etc. These raw materials have high strength, durability, and plasticity, which can provide better performance and quality for aluminum veneer.

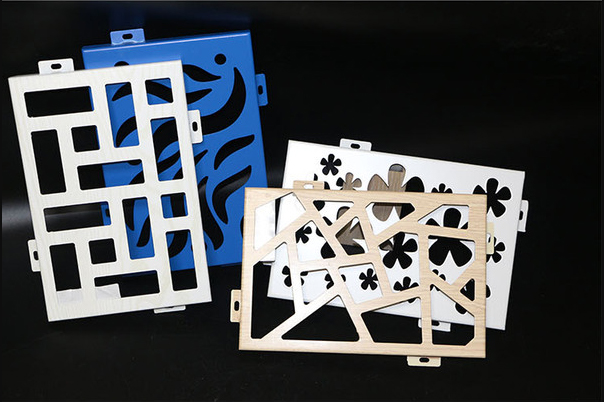

The manufacturing of high-end aluminum veneer requires advanced production processes and technologies, such as CNC machining, spraying, anodizing, etc. These processes and technologies can create finer, more beautiful, and durable patterns and textures on the surface of aluminum veneer, while also improving its waterproof, anti fouling, and anti-corrosion properties.

Specifically, the manufacturing process of high-end shaped aluminum veneer includes the following aspects: firstly, material preparation. Select suitable raw materials for processing and production based on customer needs and design requirements. The second is CNC machining. Using CNC machine tools for precision machining and engraving of aluminum veneers to form the desired patterns and shapes. The third is spraying. Use spraying equipment to spray the surface of aluminum veneer to form the desired color and glossiness. The fourth is anodizing. Perform anodizing treatment on the sprayed aluminum veneer to create a more wear-resistant, corrosion-resistant, and aesthetically pleasing surface effect. The fifth is quality inspection and packaging. Conduct quality inspection and packaging on the produced aluminum veneer to ensure product quality and safe transportation.

The manufacturing of high-end shaped aluminum veneer is a very complex and sophisticated manufacturing process that requires the use of high-quality raw materials and advanced production processes and technologies. Through continuous exploration and innovation, we can create various high-end shaped aluminum veneer products that are more beautiful, practical, and durable for people.

Customer service QQ

Customer service QQ