Industry information

Company News

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

- Aluminum veneer, a fashionable tool for creating modern architecture!

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

- Aluminum veneer curtain wall, a delicate interpretation of architectural aesthetics

- The Beauty of Aluminum Curtain: The Flow of Light and Shadow, the Gorgeous Coat of Modern Architecture

Industry dynamics

- Aluminum veneer: a metal artwork in modern architecture

- How to solve the environmental problems in the production process of aluminum veneer?

- The Beauty of Aluminum Curtain: The New Favorite of Modern Architecture

- 2.0mm aluminum veneer produced using wire drawing technology brings a new trend to construction engineering

- What are the environmental performance advantages of aluminum veneer?

Frequently asked questions

- What is the color stability of aluminum veneer?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

- Can the decorative effect of aluminum veneer be customized?

- Will the use of aluminum veneer affect the ventilation effect of buildings?

- Can aluminum veneer be used for building ceiling design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The entire process from design to installation of exterior wall carved aluminum veneer construction

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 20, 2025 19:25:36

- Click:0

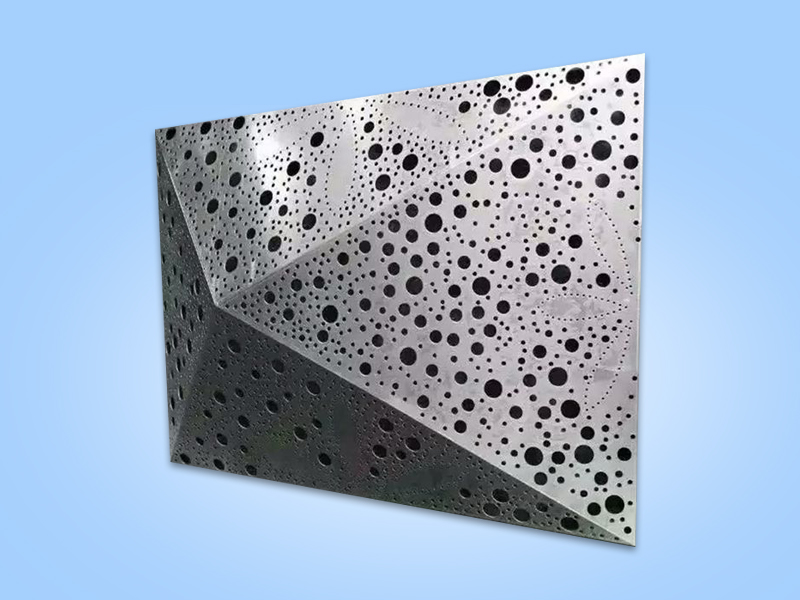

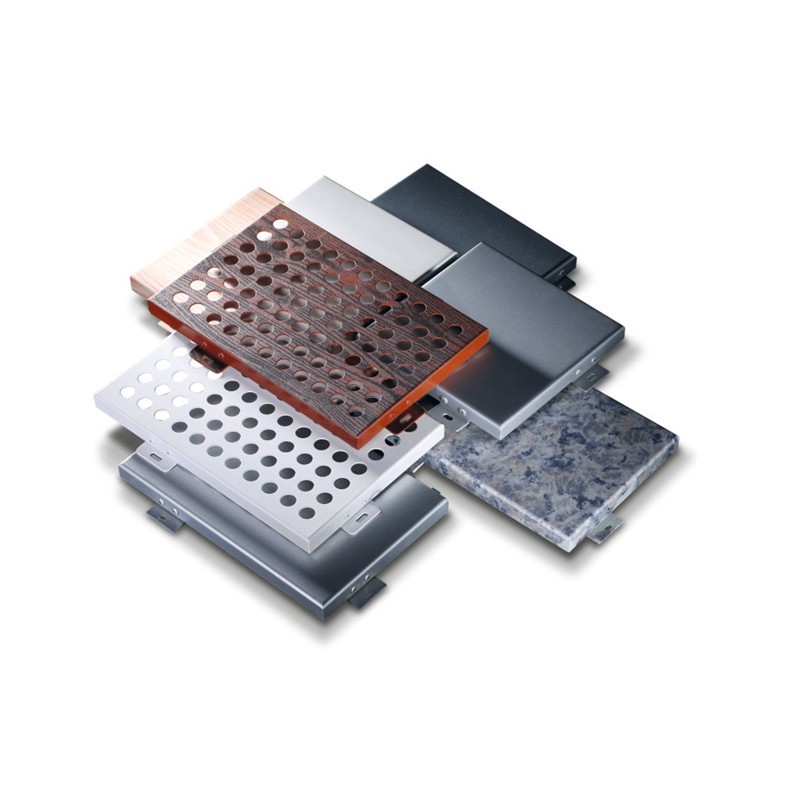

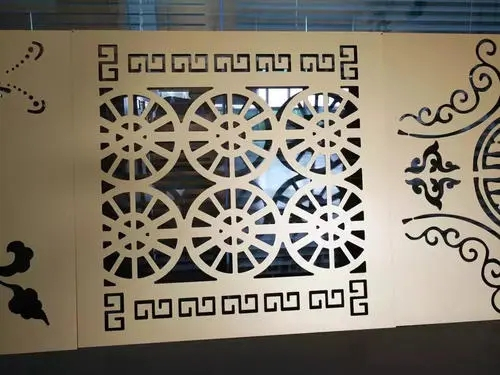

Exterior wall carvingAluminum veneerIt is a new type of building material that has been widely used in modern architectural decoration. The entire construction process of carving aluminum veneer on the exterior wall, from design to installation, requires multiple steps. The following will provide a detailed introduction to the entire process.

1、 Design proposal

Designers need to design based on the actual situation of the building. Designers need to consider factors such as the overall style, functional requirements, and usage environment of the building to determine the shape, size, color, etc. of perforated aluminum panels. Designers also need to choose appropriate perforated aluminum veneer materials and surface treatment methods based on the actual situation.

2、 Measurement and laying out

After the design scheme is determined, measurement and laying out work need to be carried out. Measurement personnel need to accurately measure the exterior walls of buildings to determine the size and position of perforated aluminum panels. The laying personnel need to mark the exterior walls of the building based on the measurement results for subsequent installation work.

3、 Preprocessing

Before installing perforated aluminum panels, they need to be pre treated. Pre treatment includes steps such as cleaning, rust removal, and polishing to ensure the cleanliness and smoothness of the perforated aluminum veneer surface. It is also necessary to perform size correction and horizontal adjustment on the perforated aluminum veneer to ensure its flatness and verticality after installation.

4、 Install fasteners

Before installing perforated aluminum veneer, it is necessary to install the fixing components first. Fixed components are usually fixed using expansion bolts or anchors to ensure the stability and safety of perforated aluminum veneers.

5、 Install perforated aluminum veneer

After the installation of the fixed components is completed, the installation of perforated aluminum veneer can begin. During installation, it is necessary to follow the requirements of the design plan to ensure that the position and angle of the perforated aluminum veneer meet the design requirements. Attention should also be paid to the treatment of gaps and connections between perforated aluminum veneers to ensure their aesthetics and integrity.

6、 Surface treatment

After the installation of perforated aluminum veneer is completed, surface treatment is also required. Surface treatment is usually carried out by spraying, anodizing and other methods to enhance the weather resistance and corrosion resistance of perforated aluminum veneer. It can also increase its aesthetics and texture.

7、 Inspection and acceptance

Inspection and acceptance of perforated aluminum veneer are required. Inspectors need to inspect the flatness, verticality, and gaps of perforated aluminum veneer to ensure that it meets design requirements and construction standards. If any problems are found, they need to be adjusted and repaired in a timely manner.

The entire construction process from design to installation of exterior wall carved aluminum veneer requires multiple steps, each of which must be strictly operated according to standards. Only in this way can the quality and aesthetics of perforated aluminum veneer be guaranteed, adding a unique charm to the building.

Customer service QQ

Customer service QQ