Industry information

Company News

- Aluminum veneer customization, creating personalized spatial aesthetics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer, a fashionable tool for creating modern architecture!

- Aluminum veneer customization: an artistic journey to create personalized spaces

- The modern charm of aluminum veneer: a perfect encounter between lightness and fashion

Industry dynamics

- Customize aluminum veneer to create personalized home aesthetics

- Curtain wall aluminum veneer: the beauty of architecture, highlighting details

- Aluminum veneer, the 'green coat' of modern architecture

- Aluminum veneer: a modern interpretation of architectural aesthetics

- What are the thickness and specifications of aluminum veneer?

Frequently asked questions

- Can aluminum veneer be used for building ceiling design?

- Can the insulation function of aluminum veneer save energy?

- What is the thermal expansion coefficient of aluminum veneer?

- Will the use of aluminum veneer affect the ventilation effect of buildings?

- Can aluminum veneer be applied to the exterior renovation of historical buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analyzing the fire resistance of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 25, 2025 05:56:24

- Click:0

Aluminum veneerAs a new type of building material, it has the characteristics of lightweight, corrosion resistance, and fire resistance, and is widely used in the field of building decoration. The fire resistance of aluminum veneer is one of its important application characteristics. Below, we will analyze the fire resistance performance of aluminum veneer.

1、 Material characteristics

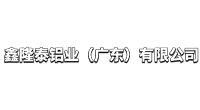

The main raw material for aluminum veneer is aluminum, which is a highly fire-resistant metal material. According to national standards, the melting point of pure aluminum is 660 ° C, while the melting point of general aluminum alloys is between 400-500 ° C. Aluminum veneer has good fire resistance.

2、 Surface treatment

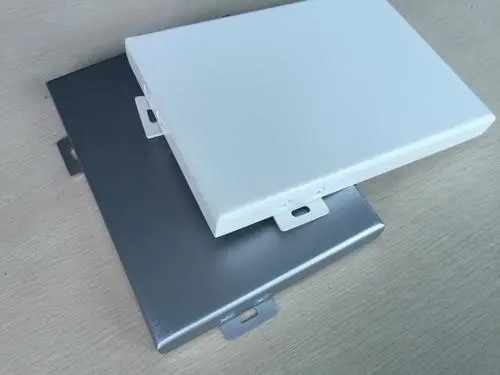

The surface treatment of aluminum veneer usually adopts techniques such as anodizing and electrophoretic coating. These technologies are environmentally friendly treatment methods using water as a solvent, which will not affect the fire resistance performance. These treatment methods can also improve the corrosion resistance and wear resistance of the surface of aluminum veneer, extending its service life.

3、 Construction Design

The structural design of aluminum veneer is also one of the important factors affecting its fire resistance performance. In the design process of aluminum veneer, the rationality and stability of its structure should be considered to avoid problems such as structural loopholes and gaps. Attention should also be paid to the isolation of aluminum veneer from the surrounding environment to prevent the spread of fire.

4、 Usage environment

The usage environment of aluminum veneer is also one of the important factors affecting its fire resistance performance. When using aluminum veneer for building decoration, relevant regulations and standards should be strictly followed, such as the regulations for non combustible materials. Attention should also be paid to the connection method and structural design between aluminum veneer and other materials to avoid safety hazards.

The above four aspects are one of the main fire performance analyses in the current aluminum veneer industry. In the future, with the continuous improvement of people's awareness of building safety, the aluminum veneer industry will continue to develop towards a safer and more reliable direction.

Customer service QQ

Customer service QQ